DynaMAX Predictive Series

Waterjet Pump

The new DynaMAX waterjet pumps with predictive maintenance, incorporate patented Seal Maintenance Technology™ and service-friendly capabilities that substantially reduce maintenance costs and disruption caused by non-planned service. With standard features such as Advanced Intensifier Technology™ and closed loop proportional pressure control, these latest generation waterjet systems offer you even more consistent cut quality while ensuring improved reliability and easy, straightforward service.

Seal Maintenance

Technology50 or 60 HP

Pump MotorPredictive

Maintenance

Improving productivity through prediction.

Increased Productivity and Reduced Maintenance Costs

Seal Maintenance Technology extends seal life utilization by up to 40%. The system monitors weepage and lets you know when it’s time to change intensifier seals – no more costly changing too soon or too late! This increases productivity, minimizes scrap, and saves time, aggravation, and money.

Increased Performance

Standard on all DynaMAX pumps, closed loop proportional pressure control adjusts for ambient pressure and temperature, oil viscosity and hydraulic system wear parts, to deliver consistent quality at optimum cutting speeds.

Improved Reliability and Ease of Service

With 10% fewer parts than earlier generations, new DynaMAX pumps include user-friendly features such as a color-coded junction box, cable harnesses, quick-connect fittings, and an easy access bleed-down valve to make maintenance faster, easier, and less expensive.

Improved Safety

Standard for “S” series pumps, a clear window cover lets the operator see the intensifier and attenuator. Optional electrical interlocks help prevent unauthorized access, and can be programmed to automatically stop the pump when opened. In addition, the seal maintenance technology’s drip tray helps keep the top deck – and the shop floor – clear of oil and water.

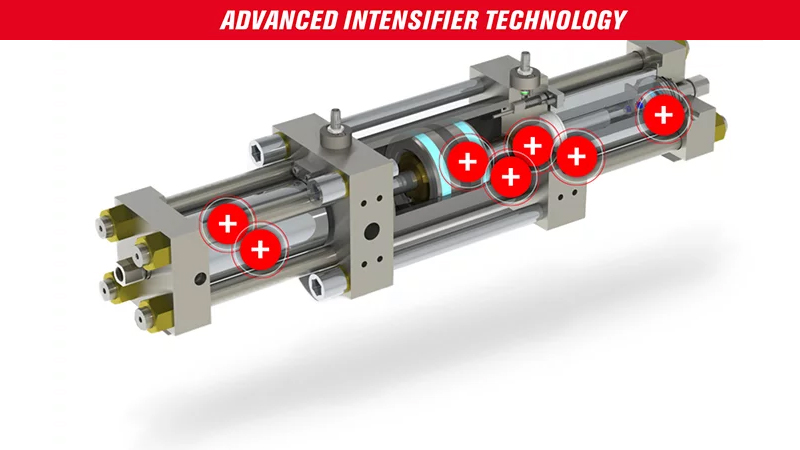

Advanced Intensifier Technology (AIT) Reduces Maintenance and Boosts Performance

Rethinking the way the intensifier pump works, DynaMAX pumps work harder, last longer, and require significantly less service time.

- Sophisticated electronics provide smooth, reliable shifting for optimum cut quality and pump performance

- Powerful, intuitive software package gives operators all the information they need to maximize uptime

- Service-friendly design simplifies high-pressure end removal for quick seal maintenance

- Check valve utilizes a screwless, low-pressure poppet design that enables quick evaluation of key contact surfaces and allows faster routine servicing

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.