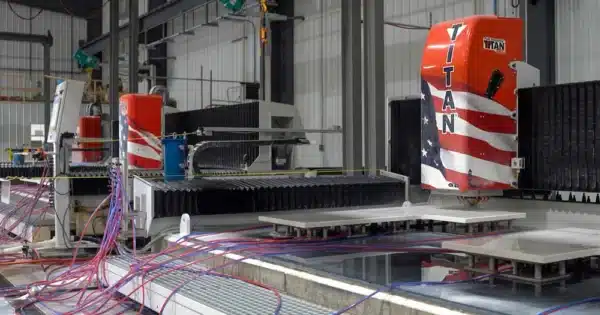

TITAN®

CNC Router Series

The legend of TITAN® forges forward with the new 4000 Series. Unmatched efficiency, uptime, and production come together as the pinnacle of CNC router productivity. This powerful combination of size, speed, accuracy, and operational ease feels beyond the realm of possibility. But not for a TITAN.

Largest Work Area

In Stone IndustryHIGH-SPEED

PRODUCTIONEasy To

Operate

Choose your Region

Please choose your region and fabrication type below.

Watch Videos

Key Features

- Production Speeds to Take You to the Next Level

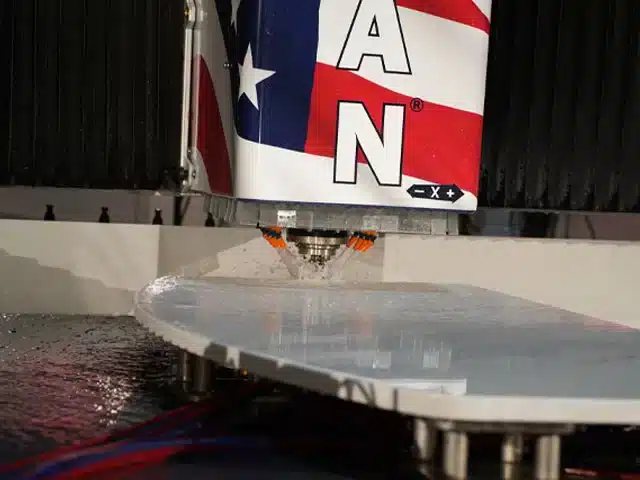

High-Speed Tooling Optimization

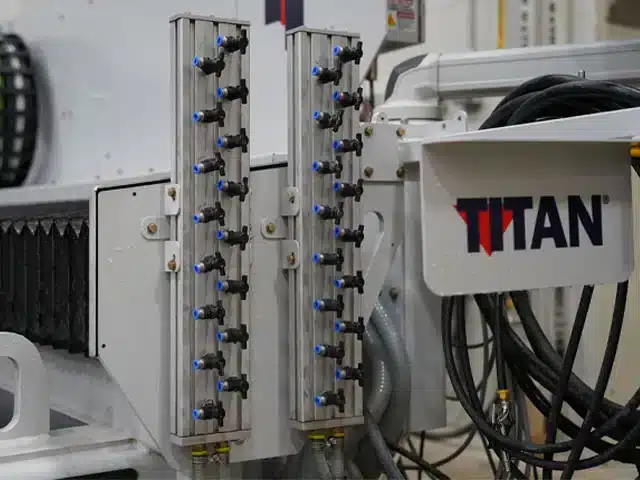

As high-speed tooling evolves, the TITAN is ready to dominate the speeds of now and the future. Built strong, it’s optimized to handle high-speed production with accuracy and longevity. It offers variable high-flow water control to meet the needs of today’s high-speed tooling.Finish Parts with 90% Less Labor

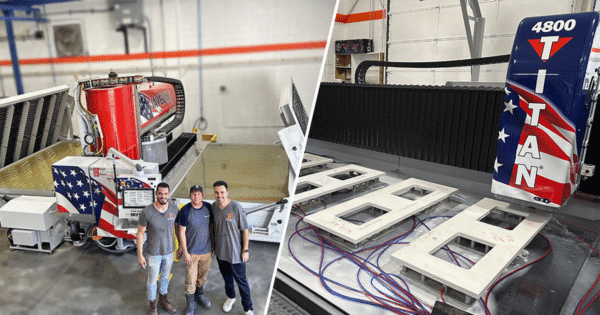

With a large table and CNC automation, the TITAN finishes parts with 90% less labor. That’s a major boost to your bottom-line profitability. Plus, you’ll never pay it overtime, give it lunch breaks, or have it call in sick.Fast Tool Changes & Rapid Speeds

With upgraded speeds, the TITAN 4000 series unleashes traverse speeds up to 2,600 inches per minute for fast out-of-cut movements and swift automatic tool changes. - The Ultimate Work Center

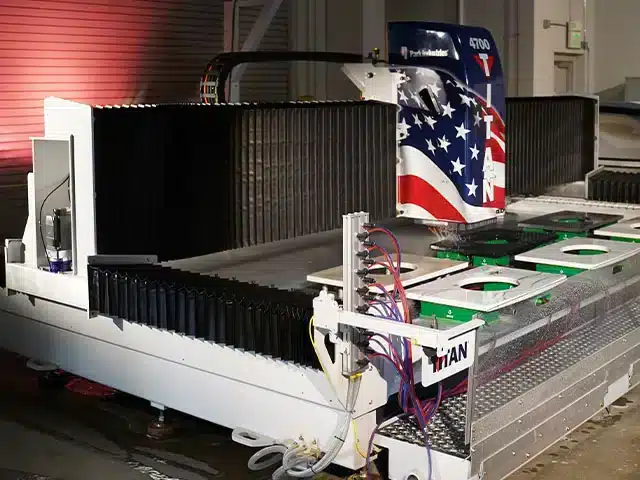

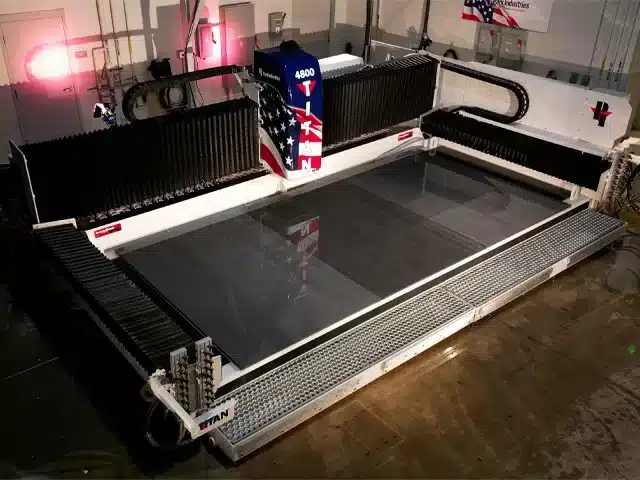

Up to 16′ 8′ Work Area

Equipped with large tables on both the 4700 and 4800 models harness every inch of the TITAN’s workspace to maximize machine productivity and efficiency. The TITAN® 4800 features an industry-leading 8’ x 16’ work area – that’s 128 square feet of usable table space.Compact Design Refined with 25% Less Footprint

The 4000 series offers a 25% reduced machine footprint over previous TITAN models without compromising work area. The 4700 model utilizes a compact, monoblock design.Expand Your Tooling with up to 68 Holders

With up to 68 tool holders in its arsenal, the TITAN 4000 series is ideal for having multiple sets of tooling on the machine and ready to run. This eliminates unnecessary time swapping tools on/off the machine for different materials or profiles. - Install-Ready Parts Straight From the TITAN

Heavy-Duty Machine Design

Built with precision in its core, the TITAN is engineered with the latest computer design and structural analysis for heavy-duty durability and unwavering accuracy. TITANs are designed and constructed with the highest quality components for

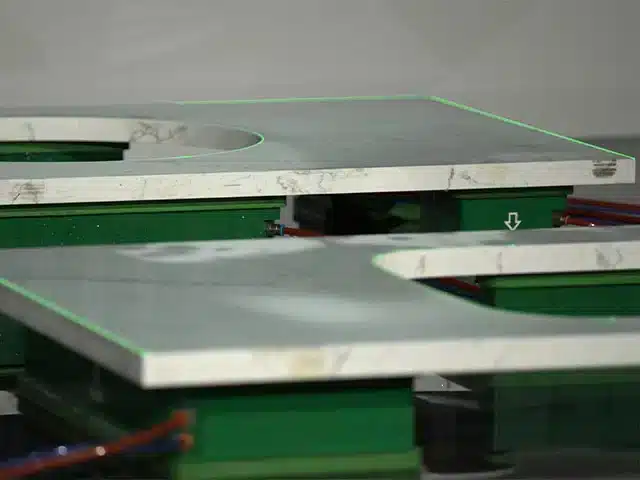

performance you can trust and depend on.Two Positioning Systems (Overhead Laser & Pin-Stop)

The overhead laser system utilizes a green laser for visual guidance, making it easy to accurately position vacuum cups and parts. Alternatively, the TITAN control system integrates with standard Pod pin-stop systems for precise placements or streamlining repetitive part placement.Available with 3 hp or 5 hp Vacuum Pump

Once the parts are in place, a 3hp vacuum pump motor ensures firm retention of parts and pods throughout the entire program. Need even more holding power? An optional 5hp vacuum pump offers additional suction power, making it ideal for higher elevation and ambient air temperature shops. - Stone's Easiest-to-Operate CNC Router

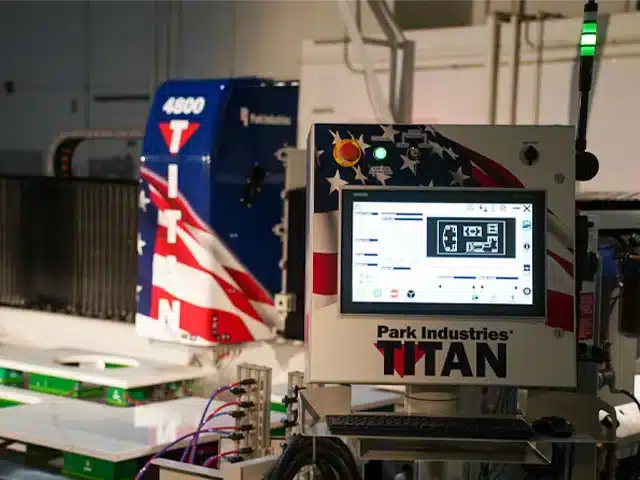

Self-Diagnostics at the HMI

With self-diagnostics, the TITAN® communicates with you like never before. It can identify issues, notify you and provide all the data you need right on the screen, making troubleshooting easy.Setting Up Tools Made Easy

Extend the life of your tooling and increase uptime with easy tool setup, measuring, and management solutions. The TITAN’s Integrated Tool Management™ system does it for you or easily integrates with leading offline tool measurement systems. Simply scan a pocket to identify which tool is set up there using our new auto tool recognition system. - Alphacam programming with exclusive Park EZ™ Buttons

Programming made FAST and SIMPLE! Park EZ™ Buttons, exclusive on Park Industries CNC machinery, make common programming tasks EZ:

- Triple your programming capacity

- Less rework with reduced errors

- Quickly onboard new programmers

Paired with Alphacam’s world-class CAD software, use over 40 built-in Park EZ™ buttons to eliminate tedious programming steps and increase your productivity. Save 60% or more of your programming time and clicks!

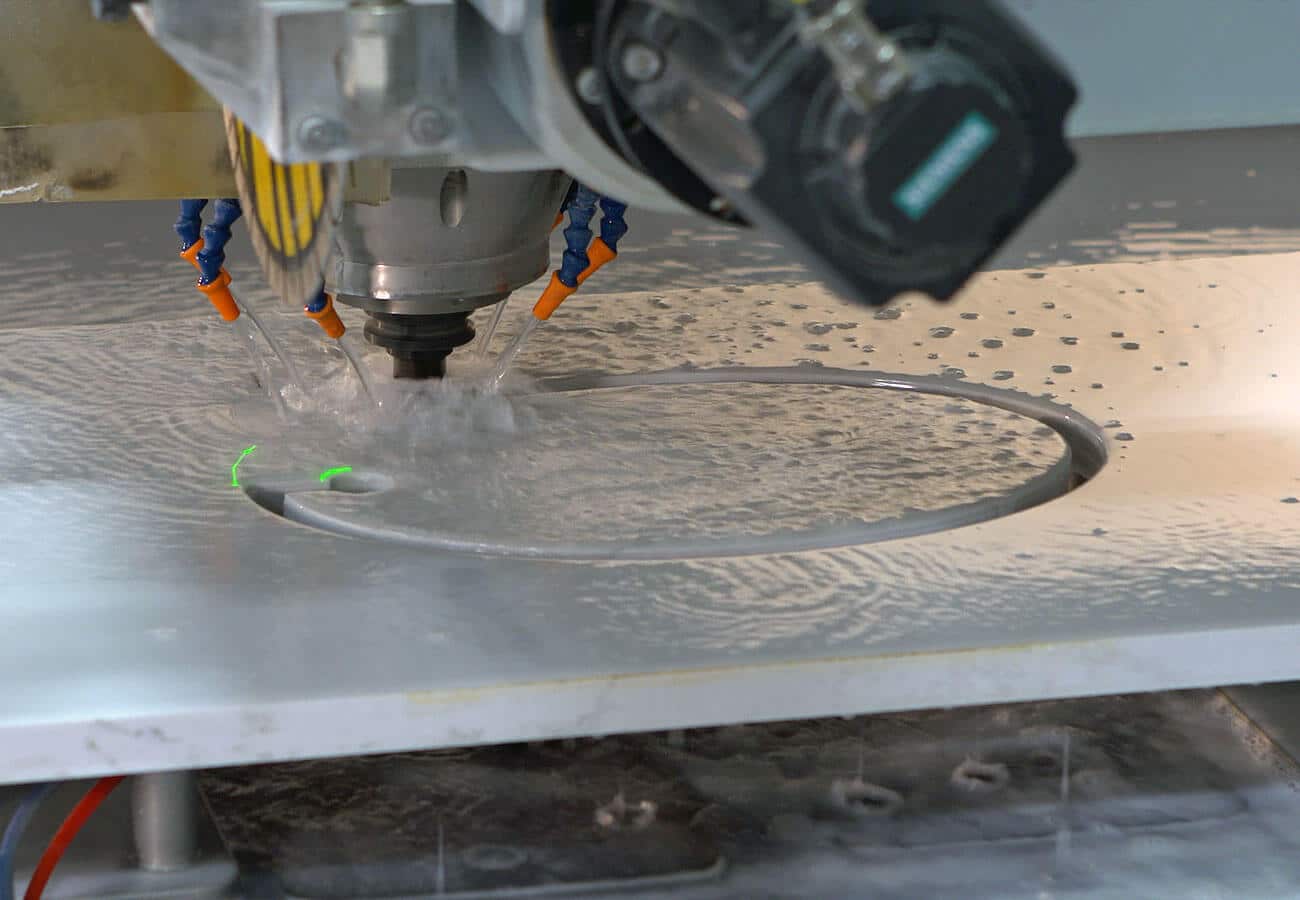

Sink Cutouts Button

Save time cutting out sinks with Park’s Sink Cutout EZ button. This feature automatically places tools in order, drops them in the correct location, and pauses the machine to remove the dropped sink before polishing. This streamlined process eliminates the chance of collision and saves valuable programming time. - Simple Operation & Controls

Large HMI Touchscreen with Multiple Languages

At the machine, the HMI control station features a large touchscreen with simple controls and multiple languages, including Spanish. The iTEC™ Interface offers easy, intuitive navigation & operation at the touch of a button.Self-Diagnostics at the HMI

With self-diagnostics, the TITAN® communicates with you like never before. It can identify issues, notify you and provide all the data you need right on the screen, making troubleshooting easy. - Experience a New Era of Maintenance Simplicity

On-Board Interactive Maintenance Schedule and Alerts

Take control and schedule preventative maintenance with custom machine notifications based on runtime. Access to the digital maintenance manual right at the control station means operators can skip searching for books and binders.Maintenance made easy:

- Automated Greasing & Automatic Strainer

- Quick-Change Water Union

- Ergonomic Operator Wall

- Safety & Water Containment

Left Side & Back Away Walls (Optional)

The optional side and back away walls eliminate the need for an obstruction-free zone around your TITAN, consequently reducing the overall footprint requirement. The back wall, equipped with a proximity switch, ensures an immediate machine halt in the event of the panel being opened. Elevate safety and efficiency with the TITAN 4000 series by integrating these advanced options.Laser Photo Eyes

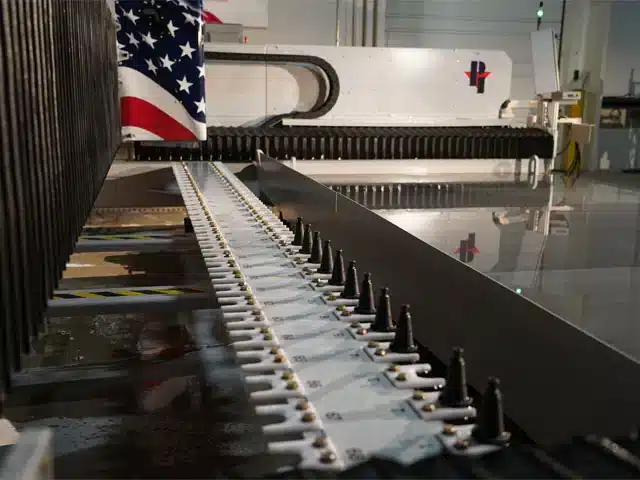

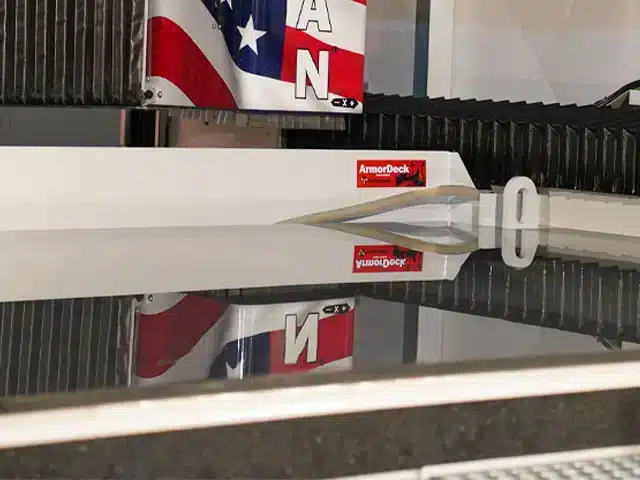

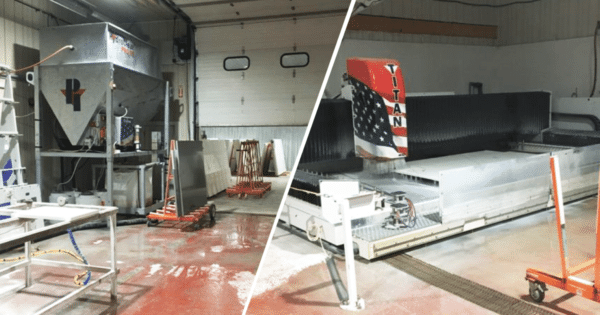

For safety, laser photo eyes are placed at the front and back of the table, creating a Photo Eye E-Stop that automatically pauses the machine if the laser is crossed. The photo eyes are convenient for tool set-up and loading the table. Additional safety cables surround the machine for added security.Water Containment & Protection

The TITAN 4000 series offers water containment and protection throughout the machine:- Front and rear water troughs with drains to collect and channel water to floor drains.

- Water containment panels (optional) to keep water spray out of walkways and channel into troughs.

- Bellow covers and tool shield to protect critical components from water spray.

- Retractable curtain

Specifications

| Select up to 3 models to compare key specs | TITAN® 4700View Layout Drawing | |

|---|---|---|

| Spindle Motor | 21 hp | |

| Spindle Type | Quantum Belt Drive | |

| RPM's | 100-8,000 RPMs variable speeds | |

| Work Area Size | 8' x 14'4" | |

| Tool Pockets | 36 | |

| Slab Thickness | 1-6 cm | |

| Vacuum Cup Options | Blick, BVC | |

| Monoblock Design | Yes | |

| Footprint including clearance (L x W x H) | 28'2.25" x 19'7.625" x 7'6" | |

| Overhead Laser Height | 12' 6" | |

| Weight | 19,000 lbs. | |

| Traverse Speeds | X/Y: 2600 IPM and Z: 650 IPM |

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.

The TITAN gives us the flexibility to cut sinks and polish edges with total confidence.

Yes, I recommend this product.

We got the TITAN to complement our JAVELIN’s cutting production. We’re getting more jobs out the door than ever before with less stress!

Yes, I recommend this product.

Our TITANs always put a great edge out and we haven’t had to do much work to them or put a bunch of money into them – which I love. Our TITANs are earlier model and we’ve had them for a long time – they just keep running.

Yes, I recommend this product.