Stone Solutions

Partner with the proven leader in designing, building, and supporting machinery for stone & granite fabricators. Since 1953.

TAX INCENTIVES

Explore the financing options and 2025 tax incentives available.

The Latest News

Get the latest from Park Industries®, from blogs to new machine announcements & more.

More Than Machinery

Park Industries® began providing full-service solutions to the stone industry in 1953. Today, we’ve grown to become North America’s largest manufacturer of stoneworking equipment.

Customer Centric

Park Industries® has invested in an infrastructure focused on providing world-class customer services and support. 22% of associates are dedicated to customer support roles.

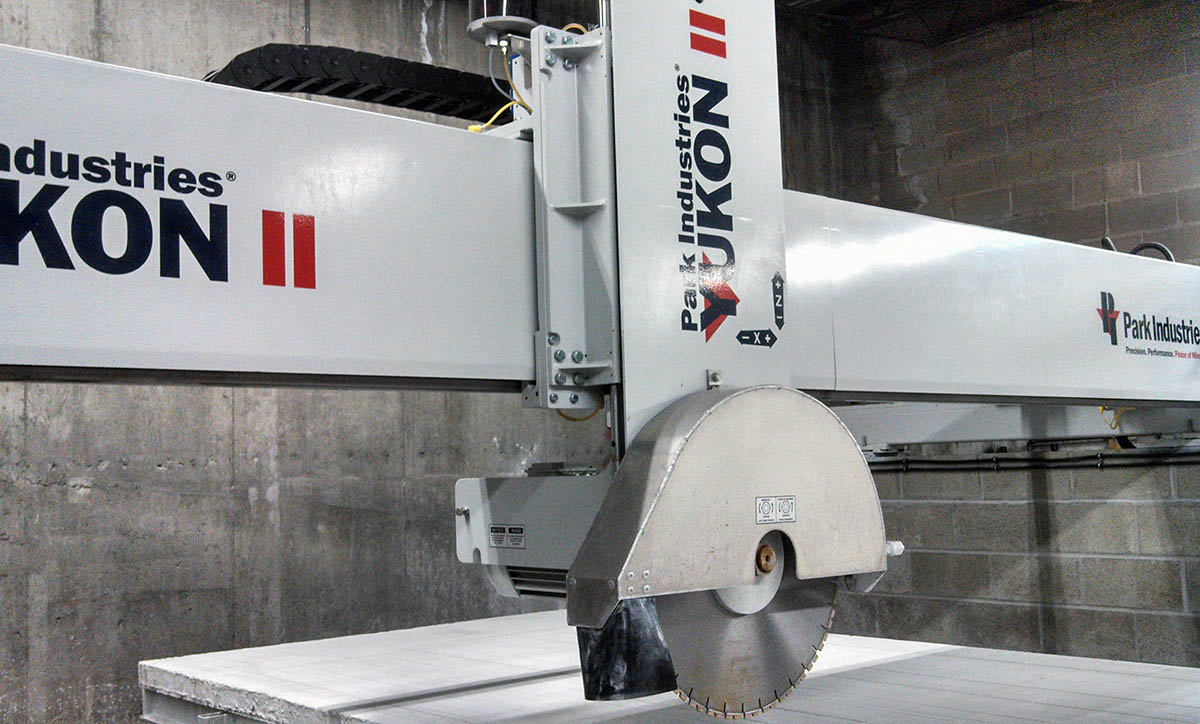

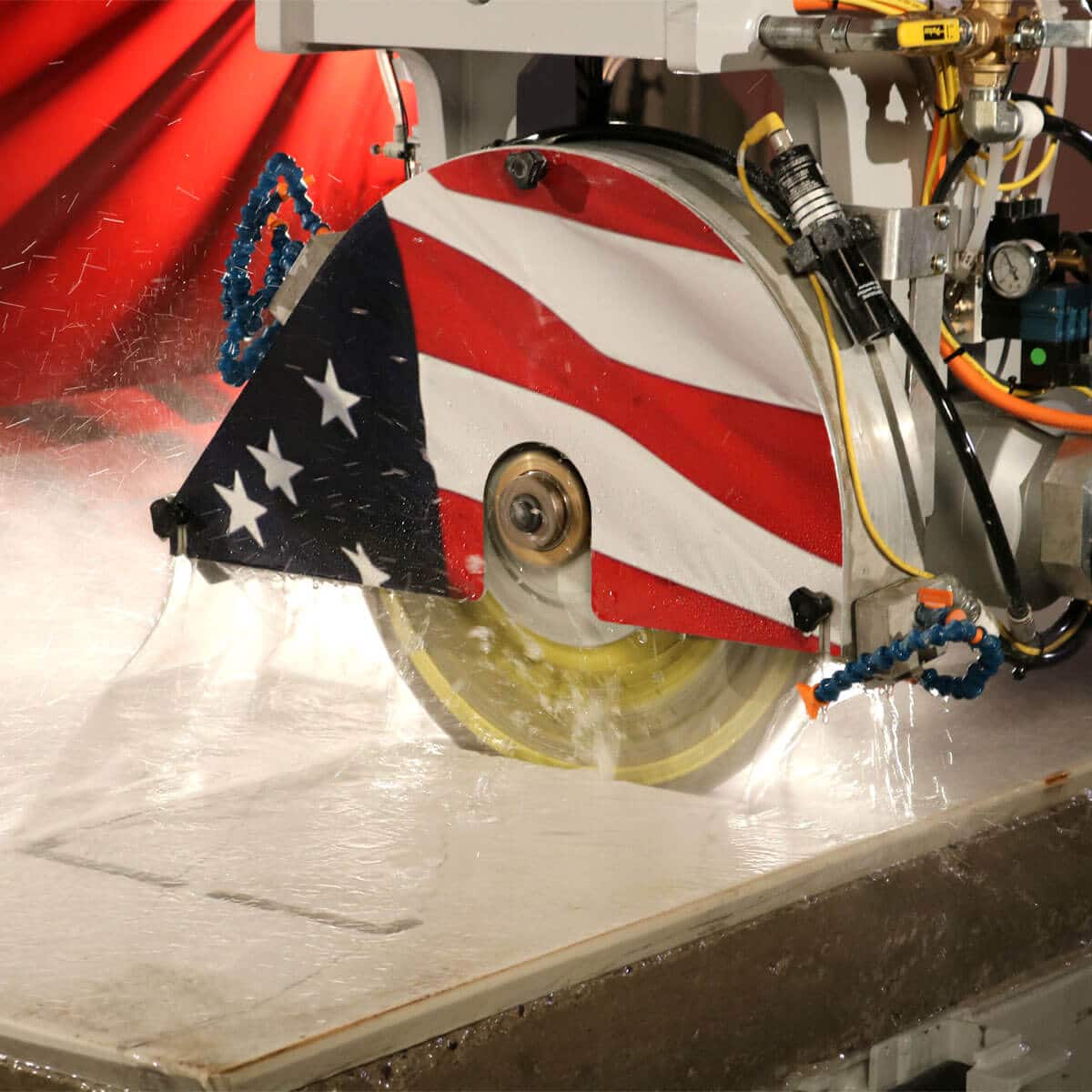

YUKON® II

Semi-Auto Bridge Saw

Increasing your output speed is easy when you use America’s most popular stone saw – the dependable YUKON® II Bridge Saw from Park Industries®. Simple, reliable, accurate – Trust your sawing needs to the YUKON® II as over 1,000 fabricators have done in North America.

0-47°

MITERSEMI-AUTO

CUTTING MODE20 HP

ARBOR MOTOR

Contact Your Sales Rep

Set Sales RegionSelect the feature you'd like to learn about or slide through them below.

BASE FRAME WITH SUPERIOR CORROSION RESISTANCE

Heavy-duty structural steel plate construction. The bridge is rigid torsion design, stress-relieved, precision-machined fabricated robotic weldment, and corrosion resistant.

MITER CAPABILITIES

The YUKON II Bridge Saw offers extremely accurate and consistent cutting with optional powered bridge miter capabilities that produces flawless, precise miter cuts up to 47 degrees.

Hydraulic TILT TABLE (optional)

360 degree manual rotation, hard stop locations every 45 degrees, central grease location, 0-70 degree powered tilt with air brakes.

Blade & Cut Depth

- 16" blade = 3-1/4" max cut depth

- 18" blade = 4-1/4" max cut depth

- 20" blade = 5-1/4" max cut depth

- 24" blade = 7-1/4" max cut depth

- 28" blade = 9-1/4" max cut depth

LASER Blade Projection

A Laser Position System projects an accurate saw path which allows operators to make any cut needed with confidence.

SIMPLE OPERATION

The intuitive controls are simple to operate and allow you to program an entire slab and give your operator complete control to make quick, quality cuts without complicated controls. A single cut go-to feature quickly advances to the next cut location with extreme accuracy, taking length and thickness into account.

A wireless pendant offers even easier operation.

BASE FRAME WITH SUPERIOR CORROSION RESISTANCE

Heavy-duty structural steel plate construction. The bridge is rigid torsion design, stress-relieved, precision-machined fabricated robotic weldment, and corrosion resistant.

MITER CAPABILITIES

The YUKON II Bridge Saw offers extremely accurate and consistent cutting with optional powered bridge miter capabilities that produces flawless, precise miter cuts up to 47 degrees.

Hydraulic TILT TABLE (optional)

360 degree manual rotation, hard stop locations every 45 degrees, central grease location, 0-70 degree powered tilt with air brakes.

Blade & Cut Depth

- 16" blade = 3-1/4" max cut depth

- 18" blade = 4-1/4" max cut depth

- 20" blade = 5-1/4" max cut depth

- 24" blade = 7-1/4" max cut depth

- 28" blade = 9-1/4" max cut depth

LASER Blade Projection

A Laser Position System projects an accurate saw path which allows operators to make any cut needed with confidence.

SIMPLE OPERATION

The intuitive controls are simple to operate and allow you to program an entire slab and give your operator complete control to make quick, quality cuts without complicated controls. A single cut go-to feature quickly advances to the next cut location with extreme accuracy, taking length and thickness into account.

A wireless pendant offers even easier operation.

BASE FRAME WITH SUPERIOR CORROSION RESISTANCE

Heavy-duty structural steel plate construction. The bridge is rigid torsion design, stress-relieved, precision-machined fabricated robotic weldment, and corrosion resistant.

Watch Videos

YUKON® II Bridge Saw | North America's Most Popular Bridge Saw

YUKON® II Bridge Saw - Cutting Architectural Applications

Key Features

- Simple to operate

The intuitive controls are simple to operate and allow you to program an entire slab and give your operator complete control to make quick, quality cuts on the hardest stone. The YUKON® II gives you the power to create precise and fast cuts without complicated controls. Diagnostic screens make the YUKON® II even more user-friendly.

A single cut go-to feature quickly advances to the next cut location with extreme accuracy, taking length and thickness into account. Powered bridge miter capabilities create accurate and clean miter cuts up to 47 degrees.

- Tools to manage stone & granite

Managing material is easy on the YUKON® II. The YUKON® II tilt table has pre-determined stop locations. It also allows stop and lock at any angle with pneumatic positioning and brakes, giving your operator complete control of the stone. Tilting capabilities, paired with the heavy-duty 360 degree rotating table allows for easy positioning.

An optional Variable Frequency Drive (VFD) allows flexibility to change blade RPM to meet your preferences.

- Customize the package tailored to your needs

Countertops or dimensional stone cut speeds up to 15 ft/minute. Configure your saw with up to a 24″ blade with a max sawing depth of 7.25″ on countertop models, and up to a 28″ blade with a max sawing depth of 9.25″ for dimensional sawing. The YUKON® II consistently creates finished dimensional stone in less time with exceptional accuracy. The 28” blade (maximum capacity) will cut slabs of granite, marble, limestone, sandstone, or bluestone up to 9 1/4” inches thick.

- On the go cutting

The YUKON® II offers a wireless pendant for easier operation, more flexibility, and faster processing. The YUKON® II also projects an accurate saw path, via a laser line guide, giving operators the confidence to make any cut needed.

- Built to last

The YUKON® II, built with a heavy-duty rigid torsion bridge design, is unmatched in reliability, and longevity with owners getting 15+ years of production out of a single saw.

Specifications

| Select up to 3 models to compare key specs | YUKON® II - CountertopsView Layout Drawing | |||

|---|---|---|---|---|

| Arbor Motor | 20 hp | 20 hp | ||

| Blade Size | 16” – 24” | 16" - 28" | ||

| RPM's | 1,750 | 1,150 | ||

| VFD | Yes | Yes | ||

| Mitering | 0-47° | 0-47° | ||

| Table / Tank Options | Powered Tilt + 360° Rotation | Powered Tilt + 360° Rotation | ||

| Cutting Surface Composition | Concrete | Concrete | ||

| Cutting Modes | Manual, Semi-Auto | Manual, Semi-Auto | ||

| Max Slab Size (L x W) | 144" x 84" | 144" x 84" | ||

| Max Cut Depth | 7.25" | 9.25" | ||

| Footprint including clearance (L x W x H) | 24'1.8125" x 25' x 9'1.5" | 24'1.8125" x 25' x 9'1.5" | ||

| Weight | 6,000 lbs. + 10,000 lbs. turn table | 6,000 lbs. + 10,000 lbs. turn table |

Related Customer Success Stories

Artistic Stone Design

Richmond, VirginiaWhen Ken Keuny took over Artistic Stone Design, it wasn’t just about acquiring an established 20-year-old stone shop;...

Richstone Surfaces

Chantilly, Virginia- Video

Richstone Surfaces, a family-owned business based in Chantilly, VA, stands as a testament to the enduring values of...

Stone City Design

Chicago, IllinoisMeet Stone City Design, an all-encompassing kitchen and bath design center, proudly owned by brother-sister duo, George and...

Chippewa Stone

Medina, Ohio- Video

With a focus on the small town values of "family, quality, and service", Oskar and Courtney Gruber of...

Honed Surfaces

Carrollton, TexasGrowing up in Stone For Matt Zafros, owner of Honed Surfaces, stone fabrication runs in the family. When...

Old World Tile & Granite

Phoenix, Arizona- Video

Priding themselves on customer service, high quality work, and a great company culture - Old World Tile &...

Mesa Fully Formed

Mesa, Arizona- Video

Equipped with seven TITAN CNC Routers and three dual-tank FUSION CNC Sawjets, Rick Bayne of Mesa Fully Formed...

Natural Stone Design Fab

Sacramento, California- Video

Natural Stone Design began in 1988 specializing in creating high-end, custom work.Since Mike & Teri Medina took over...

It is an excellent machine and Park is a company to trust.

Yes, I recommend this product.

it’s a great machine for what it’s for, but I prefer the Saber jet titan CNC

Yes, I recommend this product.

*****

Yes, I recommend this product.