If you are experiencing issues with tool detection you may see alarms like “spindle did not clamp on

tool”. Typically, this is due to a worn gripper or something is out of adjustment these are the steps that

should be taken to remedy the problem. See companion video.

Check the air cylinder gap with the drawbar extended. The tool should fit snug in the opening if it does not fit or if you can move it up and down while in the opening, you will need to adjust the gap.

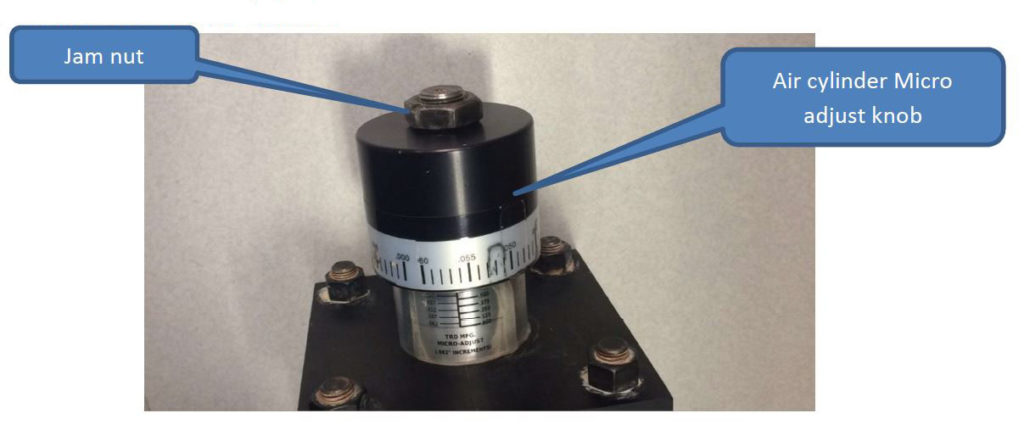

To adjust the gap, you will need to retract the drawbar then loosen the jam nut on the micro adjust knob using a 1-1/8″ wrench and turn the micro adjust knob. (If the gap is too large turn the knob counter clockwise. If it is too small turn it clockwise.) Extend the drawbar and check the gap again. Once it is adjusted tighten up the jam nut then retract the drawbar and retighten the jam nut and tighten the set screw using a 7/64″ hex key on the knob.

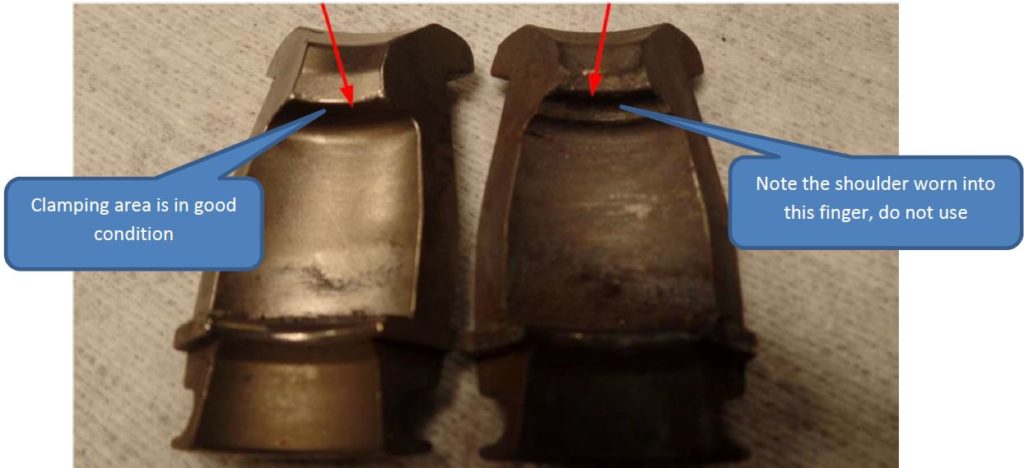

Once the air cylinder gap is confirmed then you will need to remove and check the condition of the gripper set pay special attention to the edge that lifts up on the retention knob if it is worn you will need to replace the gripper.

Extend the drawbar, install the gripper and adjust the depth to 3.573” +- 0.004” (for further help installing the gripper set see Gripper Maintenance

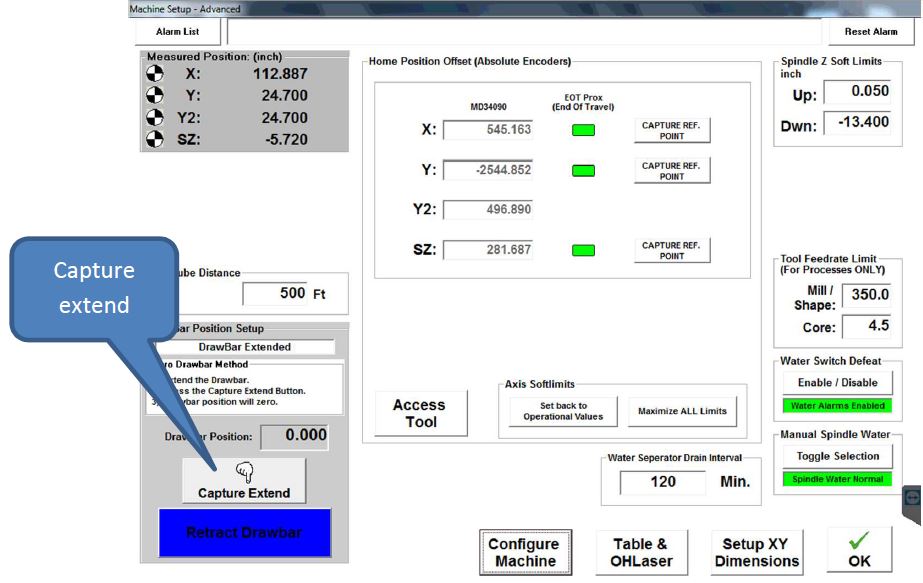

If the air cylinder was adjusted you will need to capture the drawbar position. With the drawbar extended press the capture extend button in the advanced setup screen. This will set the drawbar position to zero.

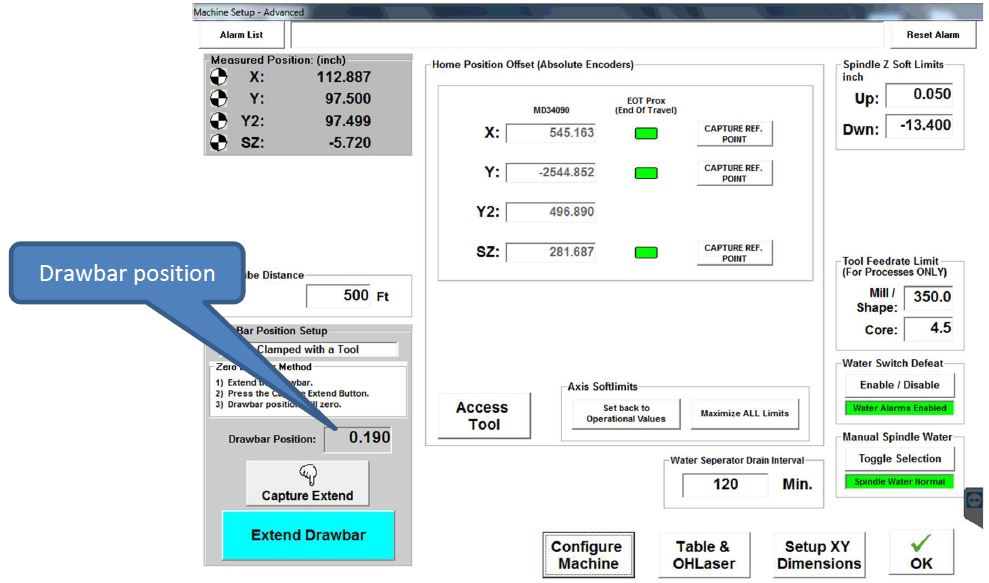

Retract the drawbar then use the manual tool change button to put a tool in the spindle and make a note of what the drawbar position is.

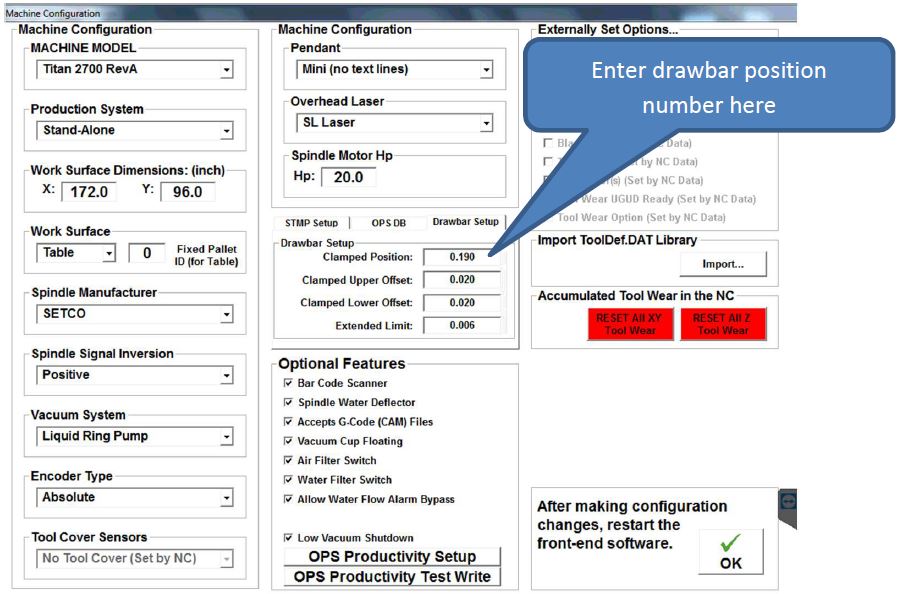

Press configure machine to get to the machine configuration screen. The password is CONFIG. Then press the drawbar setup tab and enter the number from the previous screen in the clamped position box.

Your machine should now be able to properly detect if there is a tool in the spindle or not

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.