DISASSEMBLY AND REASSEMBLY PROCEDURE

- Clean area underneath and around the table.

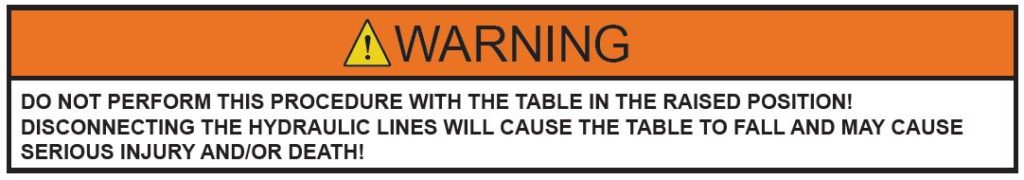

- Ensure table is in the FULLY LOWERED POSITION and power to the hydraulic pump is disconnected. (Follow any Lock Out/Tag Out procedures dictated by your company)

- Have rags nearby to catch a small amount of hydraulic oil that will come out of the hoses & adapters when they are disconnected.

- Mark the hoses so they are reinstalled on the cylinder in the same positions.

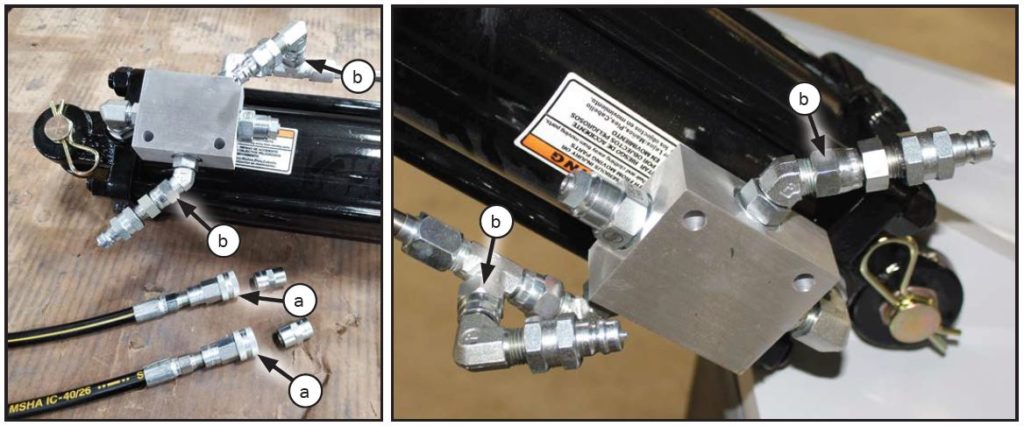

- Remove both of the female quick couplers (a) from hydraulic hoses.

- Remove both of the JIC swivel ends (b) from the hydraulic cylinder. Place a rag under the fitting to catch any oil that leaks out (only a small amount of hydraulic oil may leak out).

7. Separate the male end of the quick coupler from the JIC swivel end. (NOTE: If you have a vise available you can clamp the male quick coupler in the vise and it will be a little easier to separate the male end of the quick coupler from the JIC adapter.)

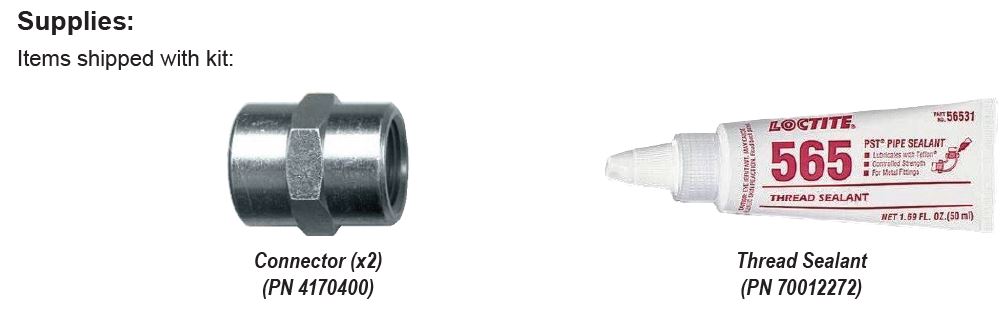

8. On the hose ends, clean threads and apply thread sealant to the threads.

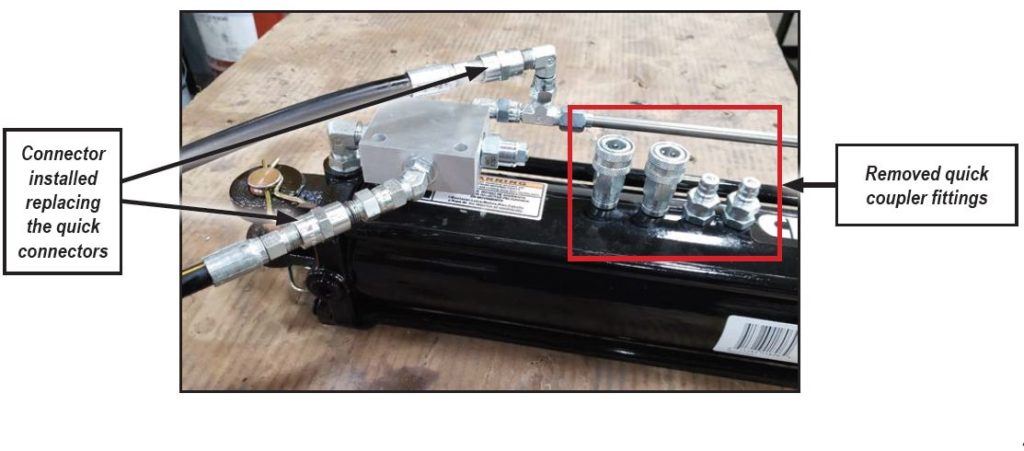

9. Thread each connector onto the hose end and tighten.

10. On the JIC adapters, clean threads and apply thread sealant to the threads.

11. Thread each JIC adapter into the coupling and tighten.

12. Reattach the hoses to the hydraulic cylinder in the same locations as marked in step 4.

13. Tighten the swivel ends of the JIC adapters, tighten to 18-20 ft-lbs of torque. (CAUTION: These fittings can be overtightened and cause them to leak)

14. Restore power to the hydraulic pump and raise and lower the table several times to purge any air out of the system. Check to ensure there are no leaks.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.