Spindles are highly engineered to provide a useful life for many years. Like other major components (e.g. car engine), routine care and maintenance are essential to prolonging the life of the spindle. Eventually, the spindle will need to be replaced but to prolong its life, it is critical that you adhere to the below specification guidelines.

Feed your CNC machine with clean water and air. Park Industries requires that water filtered to 10 microns be supplied to the spindle and water filtered to 50 microns to blade and/or halo. In addition, the dewpoint of the air should be no higher than 37.4 degrees Fahrenheit.

The CNC has filters that are designed to act as a safety device to prevent damage that may occur in the event that the air and water filter systems fail. It is a good idea to catch impurities or contaminants upstream at the source before they get to your CNC machine. If filters are plugged more often than expected, evaluate your air and water systems upstream to find the source of the problem. The machine filters are not intended to be part of the shop air and water system but rather a safety net in the event of a failure upstream.

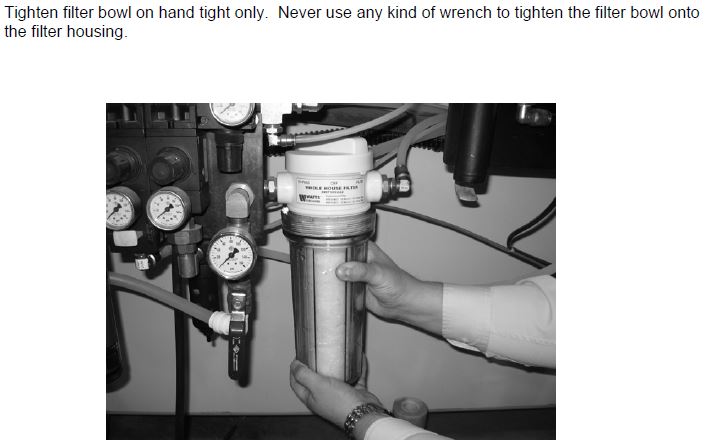

It’s good practice to change the filters on your machine, in accordance with the maintenance manual, to ensure that the safeguard filters are in good condition to catch the large particles that can potentially damage your spindle.

You have made a substantial investment in your CNC machine and we want to help you utilize this machine to its ultimate capabilities. Give it the care it deserves.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.