A step by step procedure for addressing the Mini Hopper overflowing conditions

This document outlines key elements that should be followed to maximize spindle life. Failure to follow all of these items listed below will reduce the life cycle of the spindle. Use only fresh, tap water through the spindle (per machine specifications – contact Park Industries customer service for details. Poor water quality can cause buildup […]

This procedure illustrates the steps to remove, clean and replace the Quantum Drive spindle gripper set. A companion video can be viewed also. If you have a quickset style gripper -> follow this video The Tools needed to remove/replace the gripper set are: Gripper Tool – (Figure 1) Tool tabs align with slots in gripper […]

It is very important that before running your new spindle with the used tool holders you have completed what is highlighted in the spindle care document. See Spindle Care: https://www.parkindustries.com/service/belt-drive-spindle-care/ This procedure illustrates the steps to remove, clean and replace the Quantum Drive spindle. A companion video can be viewed: Spindle Removal Video: Spindle Install […]

To help ensure you are getting the longest service life from your TITAN 1000 Series’, FabCenter, & DESTINY’s rotary union make sure the following steps are being taken when installing a new rotary union. Always make sure you are using the proper tools. ONLY use the correct size wrench to remove and install the rotary […]

The overhead laser is a positioning tool used for locating vacuum pods and parts. As the day goes on and shop temperatures fluctuate, the overhead laser accuracy is affected. As much as a half inch of error may be noticed if the laser is not calibrated before each table load of parts. There are two […]

This guide is intended to remedy vacuum issues at -19 in/Hg or less. Before starting troubleshooting, make sure these conditions are made: • Stone is in place on vacuum pods and in position on table • Vacuum Pump is ON • Verify that all appropriate manifold valves are on Verify manifold valves are in the […]

An Over-cycle alarm can be caused by several things. This list is the best way to check off the easy items and quickly find the issue. Check incoming water pressure. Be sure the main supply of fresh water for the cutting head hasn’t been shut off, or the filters aren’t dirty. In the machine setup […]

This alarm is generated when both limit proximity switches on the same axis are activated. A simple adjustment to the proximity switch normally corrects this alarm. On this machine the logic is unable to identify the precise switch. This procedure will show you how to locate and identify the proximity switch which is in need […]

This procedure lists the steps to remove and replace the lifter (rise & fall) screw nut in either the Yukon or Jaguar models of bridge saws. Similarities and DifferencesThere are two machine models: Yukon and Jaguar. The machine common names are: Yukon, Yukon II, Jaguar II, and Jaguar III. In all machines the lifter (rise […]

This document illustrates the steps required to remove and replace the lower cross travel bearings on a Jaguar or Yukon saw. Before You Start Component Identification:This photo identifies JAGUAR and YUKON bridge saw lower cross travel bearing components. The bearings ride on chrome round ways as the cross travel frame traverses the entire length of […]

Clean area underneath and around the table. Ensure table is in the FULLY LOWERED POSITION and power to the hydraulic pump is disconnected. (Follow any Lock Out/Tag Out procedures dictated by your company) Have rags nearby to catch a small amount of hydraulic oil that will come out of the hoses & adapters when they […]

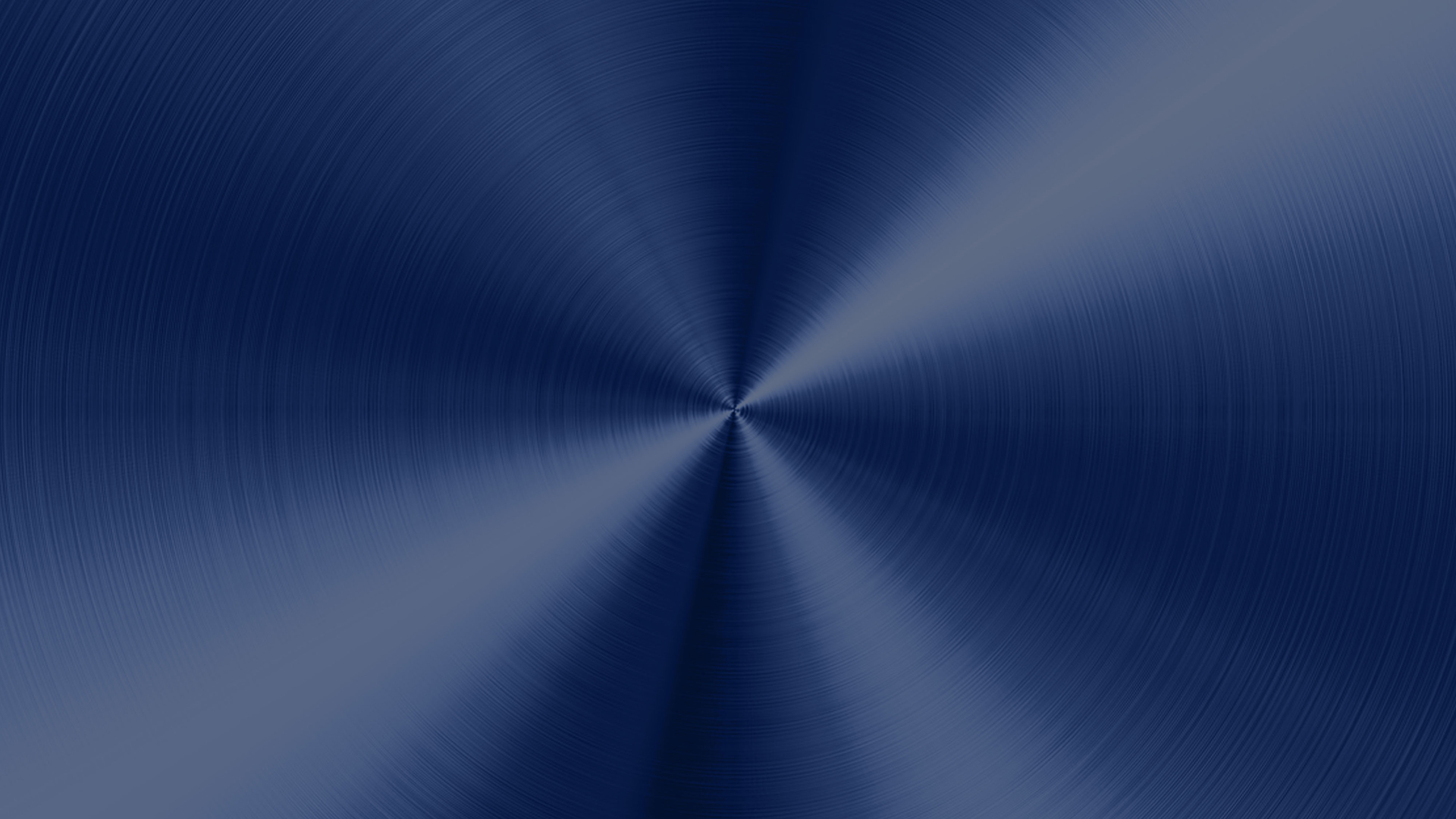

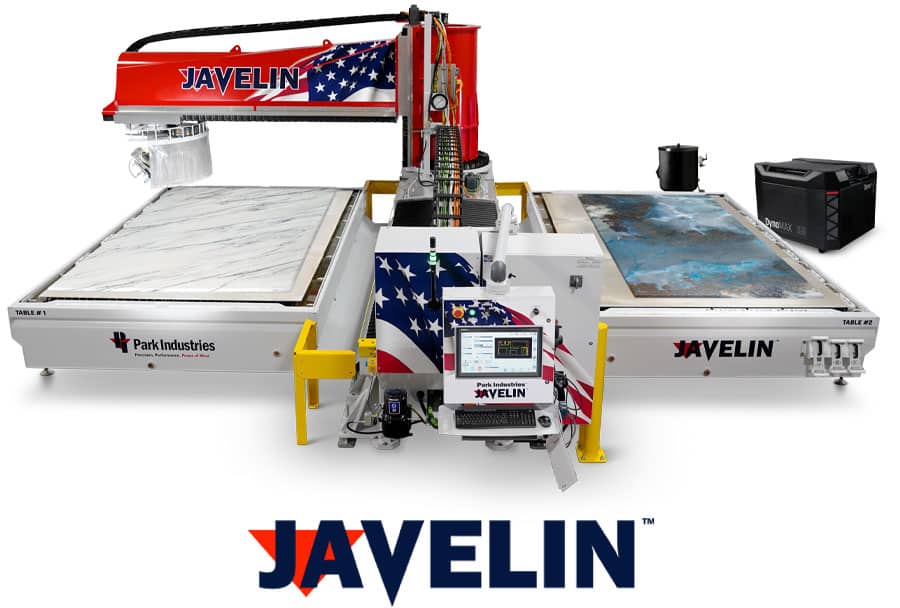

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.