How to program a Shower Pan on a CNC Tags Showerpan

How to operate and run a program on the Voyager XP

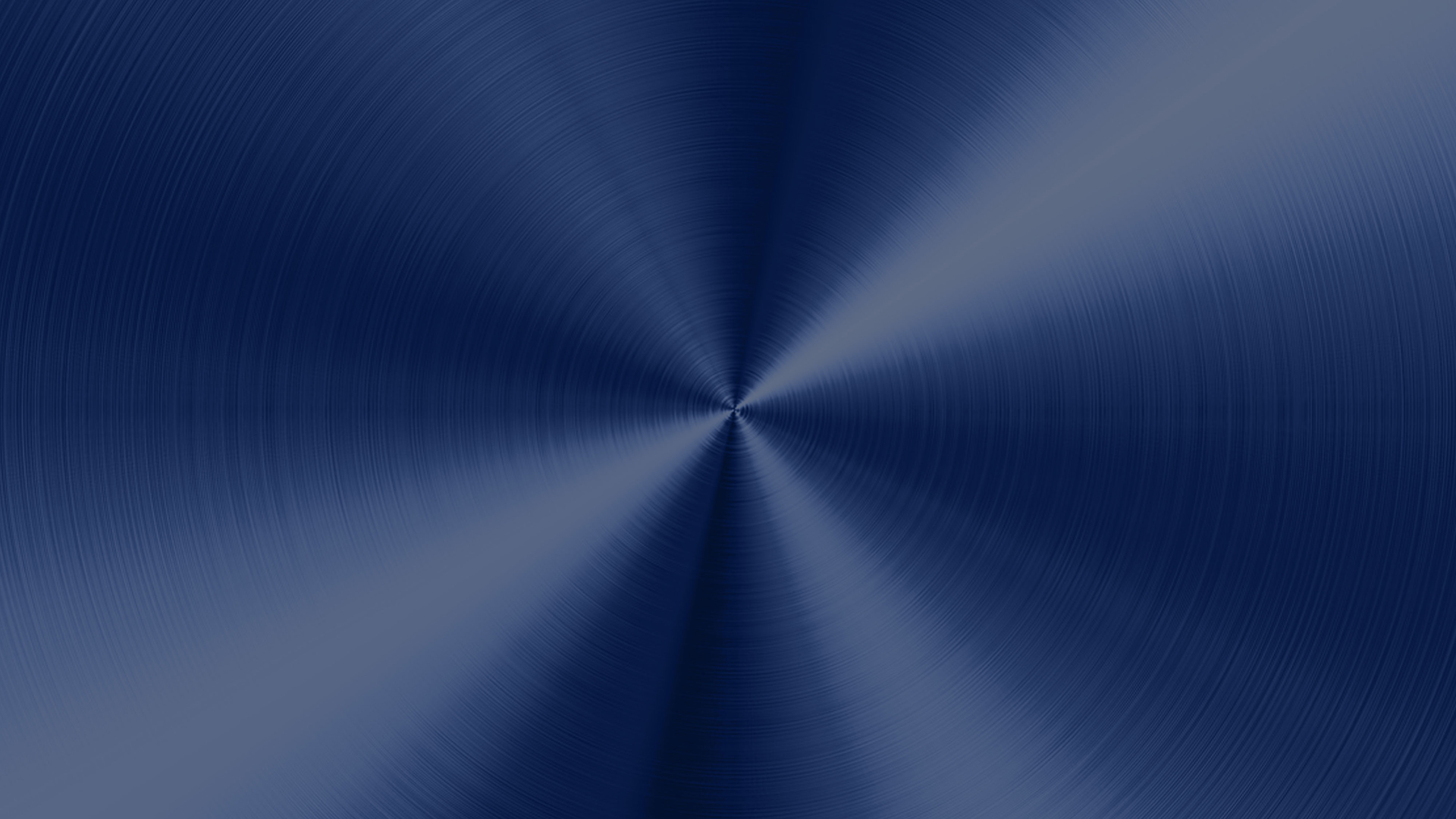

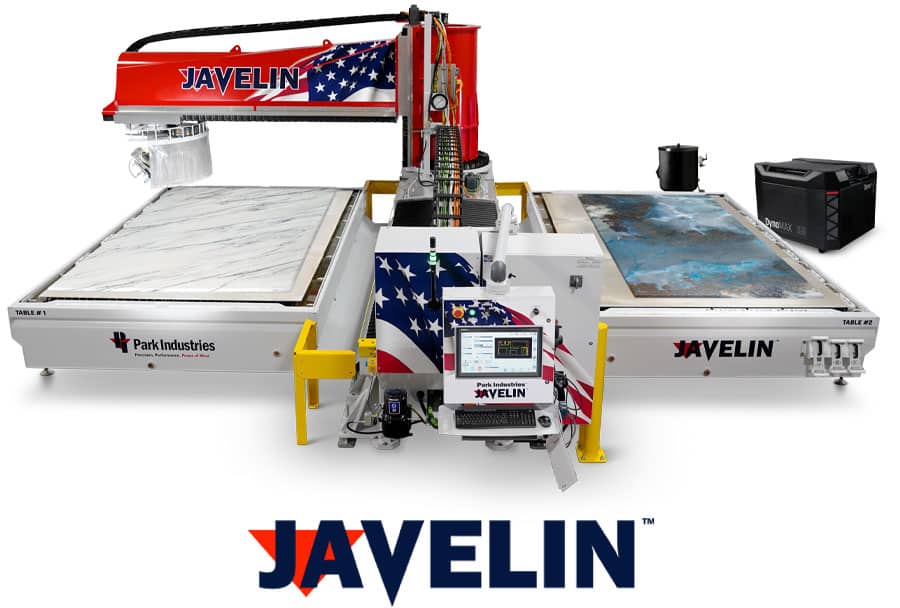

How to run a program on Park Industries Titan Router

This procedure will assist in replacing the miter gear rack and gear on Pro Edge and Tru Edge polishing machines. Miter to 0 degrees and follow your companies LOCK OUT TAG OUT procedures. Start by removing the miter motor from the miter box. Remove the motor and set it on the ground. Measure the distance […]

Predictive pump Breakdown High pressure seals and poppet This video shows how to replace the seals inside the high pressure cylinder on the intensifier. Also shows low pressure poppet and check valve servicing. The above video will show details that are broken down in seperate videos below. It was created by Hypertherm previously known as […]

Video shows how to install and setup the CrossCut saw.

This procedure will assist in adjusting or setting up a new or current Denison Hydraulic Controller. Skill Level estimated time to complete: 1 – 1 1/2 hours If your cross travel is not stopping in a consistent location, check the following. Make sure the limit flag maintains a constant distance from t he cross travel […]

This document illustrates the steps required to troubleshoot the possible causes of the overload(s) tripping for the spindle motor in the main electrical panel causing an alarm on the screen. WHILE PERFORMING THIS PROCEDURE ENSURE ALL LOCK OUT / TAG OUT POLICIES IMPLEMENTED BY YOUR COMPANY ARE FOLLOWED CLOSELY. Skill Level Estimated time to complete: […]

Video shows how to change the high pressure seals.

Video shows how to service oriface, mixing chamber and nozzle on Jet Edge Intensifier Systems.

Video shows how to service high pressure poppet, check valve and low pressure poppet.

This document illustrates the steps required to adjust the Miter Home Position Coordinate on a Velocity machine. The miter on the Velocity homes off of a proximity sensor mounted by the compensation arm on the exit end of the machine. If this proximity sensor is adjusted, moved, or replaced the following steps need to be […]

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.