With all Park Industries machines, Todd Branson Stoneworks tackles miter work, difficult materials, and more with exceptional accuracy and speed.

Todd Branson Stoneworks

In 2000, Todd Branson founded Todd Branson Stoneworks as a two-man operation out of a garage in Oahu, Hawaii. His commitment to quality and his customers laid the foundation for what would become a leading stone fabrication business on the island.

Todd’s focus on high-quality work and intricate projects, along with precision CNC machinery from Park Industries, has driven the evolution of his stone shop.

Quick Facts

LOCATION

Oahu, Hawaii, USA

TYPE OF FABRICATION

High-End Custom Projects

PARK EQUIPMENT

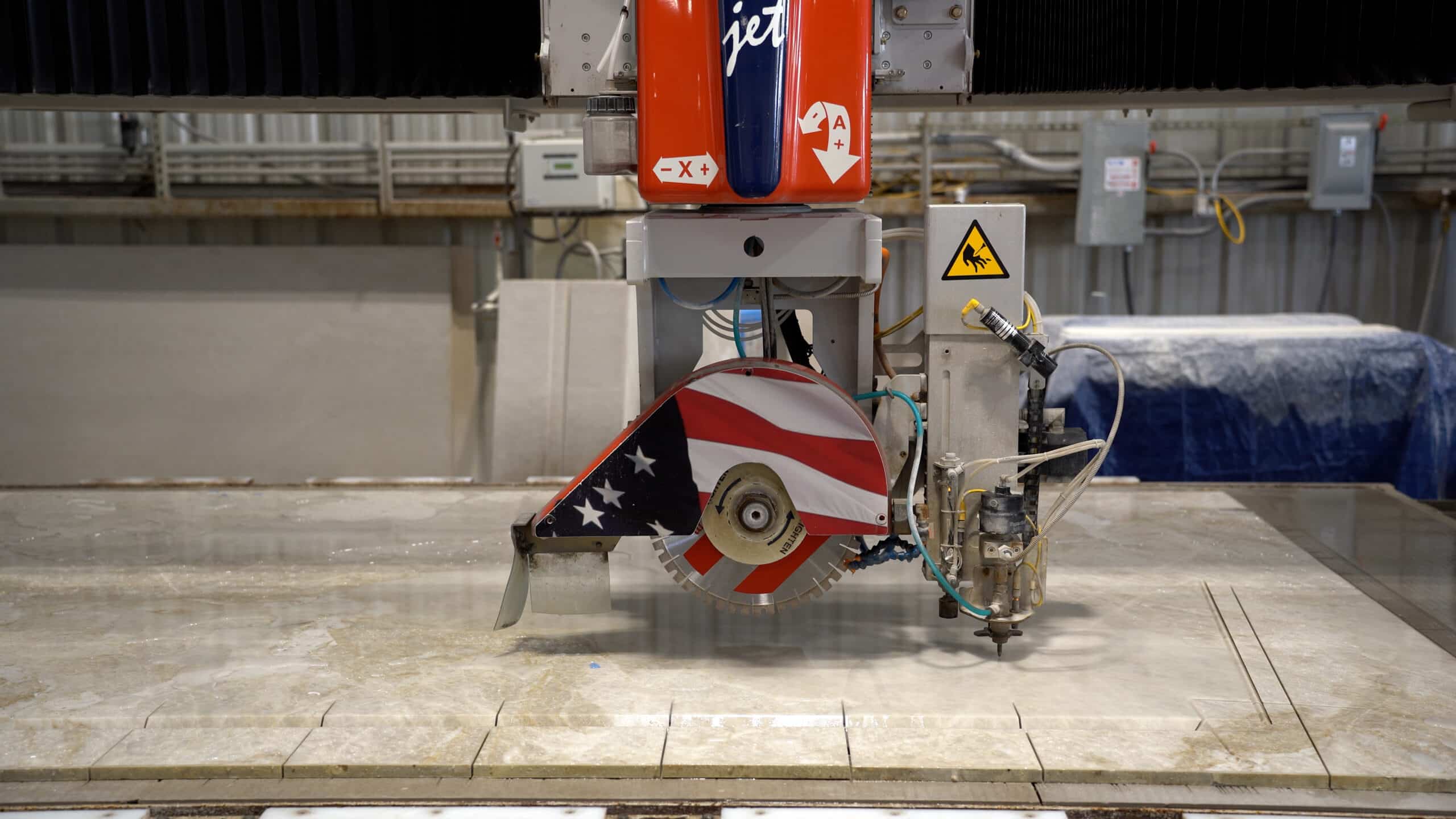

SABERjet™ XP CNC Sawjet

SABERjet™ CNC Sawjet

TITAN® 3700 CNC Routers

FASTBACK® II Edge Polisher

SlabVison™ Slab Scanner

HydroClear™ PRO 140 Water System

PARK PARTNERSHIP

Began in 2010 with a FUSION 4045 CNC Saw & TITAN 1800 CNC Router.

Partnering with Park Industries®

Todd’s journey with Park Industries® began in 2009 at TISE, where he noticed the buzz surrounding their booth. Intrigued, Todd engaged in his first conversations with the Park team and later attended the Digital Stoneworking Expo™ (DSE) in 2010, where he saw how digital fabrication and CNC machines could transform his business.

Impressed with how efficient the digital fabrication process was, Todd made the decision to go all in – investing in a CNC sawjet, CNC Router, and Digital Photo Station – all from Park Industries. “When I saw how the different machines worked together, it just made sense to purchase the whole package,” he explains.

Fast forward 14 years, and Todd is now proudly serving as a host for Park’s first DSE event in Hawaii, a moment made possible with his long-lasting partnership with Park Industries®.

Mitering Made Easy with SABERjet™ CNC Sawjet

Fast forward to 2024, Todd has continued to elevate his shop’s capabilities by upgrading his machinery for maximum precision and accuracy. He now benefits from two SABERjet CNC Sawjets — one SABERjet and one SABERjet XP. “The SABERjet XP, especially, has really provided us with extra cutting capabilities. It has increased horsepower, a variable frequency drive (VFD) motor, and ultracompact automation that help us take on various materials with ease,” Todd explains.

“The 5-axis waterjet capabilities make it a lot easier for inside 90-degree corner mitering,” he adds, noting that this feature significantly reduces chipping and keeps the job cleaner. With the SABERjet duo at his disposal, Todd’s team can efficiently tackle a large volume of high-end projects with remarkable precision. “With the speed, accuracy, and automation of these sawjets, we’ve easily tripled our cutting production capabilities, even when cutting complex miters or slower materials like quartzite,” Todd shares.

flawless Edges Thanks to the TITAN® CNC Router

The TITAN CNC Router has been key to creating perfect seams and precise scribing in Todd’s projects. “The TITAN helps us make very tight seams. It’s helped us with our three-step process for seaming that makes them almost unnoticeable,” Todd shares. This precision has allowed his team to scribe pieces to walls with minimal caulking. “We’re doing a lot of scribing to walls, and they’re fitting so well that they’re almost caulkless,” he adds. The TITAN’s efficiency has not only improved production but also reduced the dust in the shop — a major need for shops today amidst new silica laws.

Todd’s shop has experienced faster production with the TITAN, which has greatly reduced labor costs. “The TITAN saves us so much time by shaping and profiling with precision,” Todd explains. The machine’s ability to handle complex designs & knock out sinks means Todd’s team can take on more projects while maintaining the high standards they are known for. “It’s not just about precision — it’s about saving time and improving our overall workflow,” he adds.

SlabVision™ Scanner Captures Every Detail

With limited space in Hawaii, the compact design of the SlabVision has been ideal for Todd’s shop. “The footprint of the SlabVision is very helpful for the limited space that we have,” Todd explains.

The scanner’s ability to provide high-quality slab imaging has been crucial for meticulous inspections. “In our market, it’s very critical we inspect the slabs very carefully. This will definitely help improve the quality we’re producing,” Todd says. The SlabVision features extremely high image detail and powerful layout software that includes vein matching in a 3D environment, which is essential for Todd’s team as they handle large, high-end custom projects that demand flawless results. This advanced technology enables them to capture every detail in the slab, ensuring a perfect end-result for their customers.

Speeding Up Production with Park Machines

The combination of Park’s machines has drastically increased the efficiency of Todd Branson Stoneworks. The speed and precision of Park’s equipment have enabled his shop to grow from a small garage to a sprawling 12,000-square-foot facility. “It’s saved time and sped up our production considerably,” Todd adds.

This investment in cutting-edge technology has catapulted Todd’s production capabilities, resulting in a remarkable 500% growth in revenue within just one year following the upgrade of CNC machines after the DSE in 2010. Today, Todd’s shop stands as a leader in serving the high-end market in Hawaii, excelling in mitering and working with a diverse range of stone materials. The integration of Park’s advanced machinery has allowed Todd and his team to refine their fabrication processes, ensuring they operate with maximum efficiency and precision while maintaining the high-quality standards their customers expect.

Endless Possibilities with Park Industries®

For Todd, the investment in Park machines has been invaluable in boosting production while ensuring the safety of his team. “Several people have called me about Park Industries, and I’ve said that Park machines will increase your production, as well as eliminate a lot of the silica dust in your shop,” he explains. The reduction in dust has created a cleaner, healthier environment, which is crucial for long-term safety in stone fabrication.

Despite Hawaii’s remote location and time zone difference, Park has consistently delivered fast, reliable service. “When we need parts for the machine, they’re here in 24 to 48 hours,” Todd says.

It’s not just about the machines for Todd — it’s the support and care that Park provides that makes all the difference. “Park’s service has truly exceeded our expectations.”

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.