After years of manual fabrication and a poor experience with service from an overseas machine manufacturer, Jim Nobes has finally found the machine provider who is right for his company Nobes Granite in Stirling, Ontario. By partnering with Park Industries, Jim has been able to go digitize his production process to enhance its efficiency and product quality with a variety of machines. This has helped him grow his business significantly, and he’s done it all as the only person in the fabrication shop.

Transforming Operations with Park Industries

Jim’s journey with Park Industries began as a one-man shop doing everything by hand. When he decided to invest in machinery for the first time, he purchased machines from Italy. After an issue with one of his machines, he experienced frustrating downtime due to waiting around on parts and hard to get a hold of tech support. Eventually, it reached a boiling point with Jim who was done with it. He took a forklift and gratifyingly put one of the machines in the dumpster behind his shop. He recalls, “My neighbors thought I was crazy.”

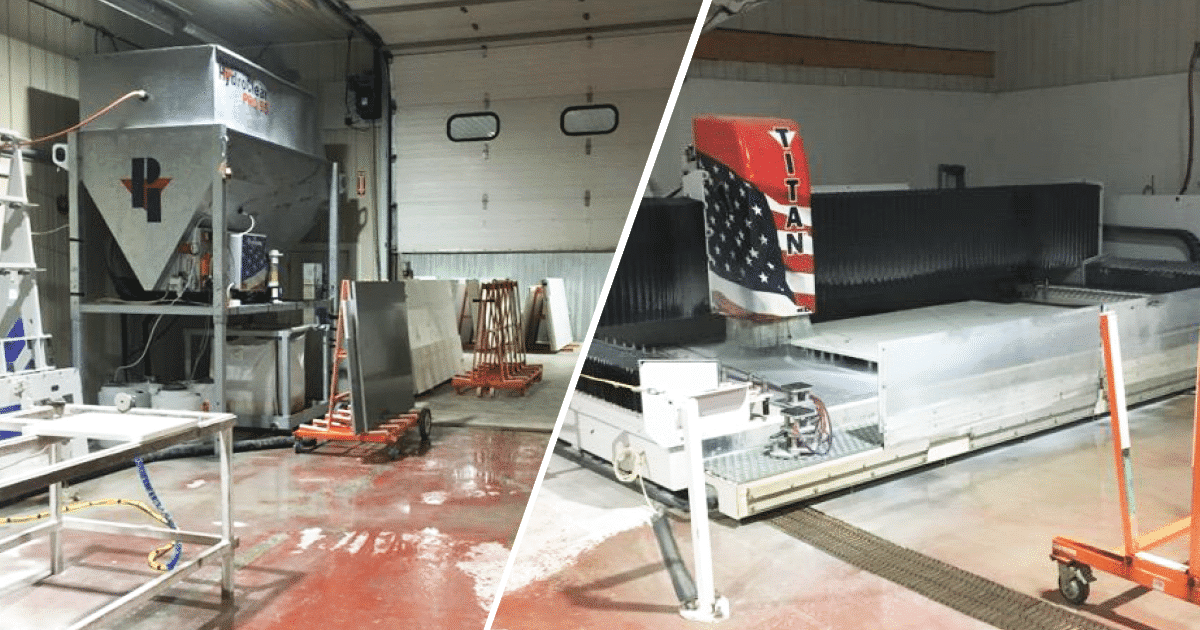

After a friend’s recommendation to go digital with Park, Nobes Granite first got the cutting machine of their dreams, the SABERjet XP CNC Sawjet. Next, they needed a way to knock out flat edge polishing, so the FASTBACK II Edge Polisher was the obvious choice. Then they needed a machine to polish everything else and needed better control of their shop’s water supply so the TITAN CNC Router and HydroClear Pro 95 were added.

Jim’s shop is now fully digital and extremely efficient, with a Park Industries solution for every aspect of fabrication. He emphasizes Park’s comprehensive support, stating, “Park Industries has been there every step of the way, ensuring that my machines are always up and running smoothly.”

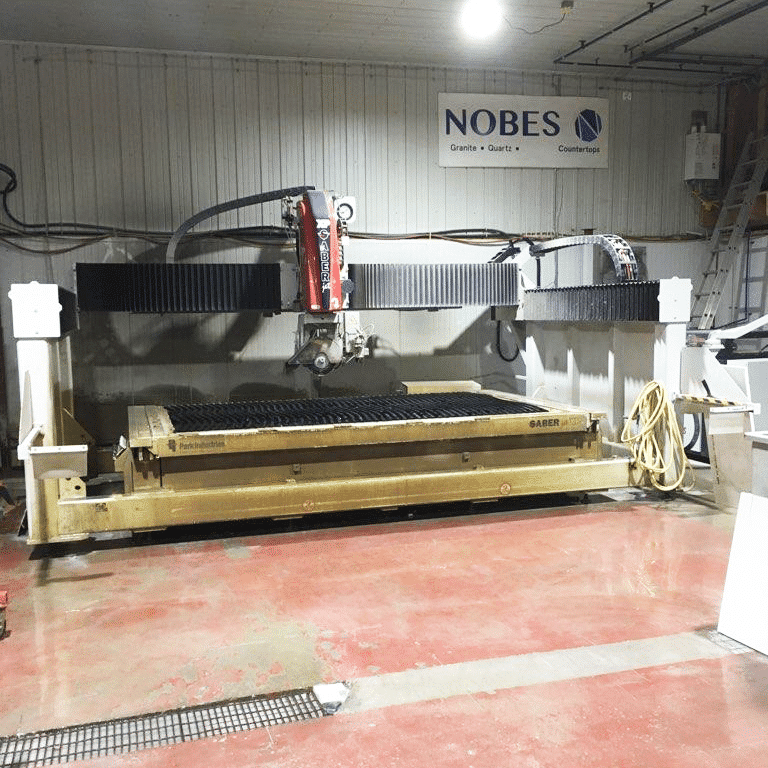

Optimizing Production with the SABERjet™ XP CNC Sawjet

With the installation of the SABERjet XP CNC Sawjet in 2020, production at Nobes Granite was immediately transformed with efficiency, precision, and overall quality improving significantly. Jim remarks, ‘The SABERjet XP has taken over tasks we used to do by hand.’

With its ability to handle intricate designs and mitered edges, the SABERjet XP has become a necessary tool in Jim’s workshop. He praises its durability for ensuring uninterrupted production, highlighting its waterjet feature that eliminates manual sink cutting. This feature not only delivers a cleaner finish, but also helps them comply with safety regulations in Canada, as it eliminated their old process of cutting/grinding sinks out which causes a lot of dust.

Jim considers the decision to go with the SABERjet XP to be one of his best. As he often says, ‘You’ll never regret buying the best.'”

Fast, perfect edges with the FASTBACK® II Edge Polisher

As soon as they got the FASTBACK II in 2021, Jim threw his hands up in the air and wondered why they hadn’t gotten one earlier. He praised its speed, calling it “phenomenally fast.” The machine’s efficiency has made them more profitable, and Jim is extremely impressed with the polishing pad life, saving substantial costs. The FASTBACK II’s simple operation and beautiful polish quality have significantly improved their workflow.

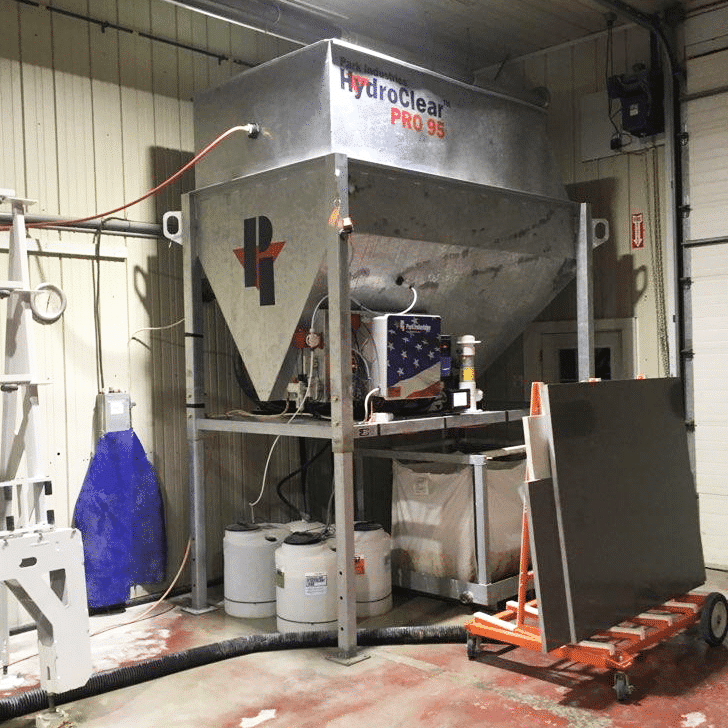

Making Every Drop Count with The HydroClear™ Pro 95

To solve the issue of limited water supply, Jim got the HydroClear Pro 95 in 2022. The results were impressive, saving $1000 on his water bill every 3 months and easily supplying his machines with water. He states, “Prior to the HydroClear, we were wasting water and throwing money down the drain.”

With nearly zero maintenance, the HydroClear is providing him peace of mind and along with aligning with his goal of being an environmentally responsible fabricator.

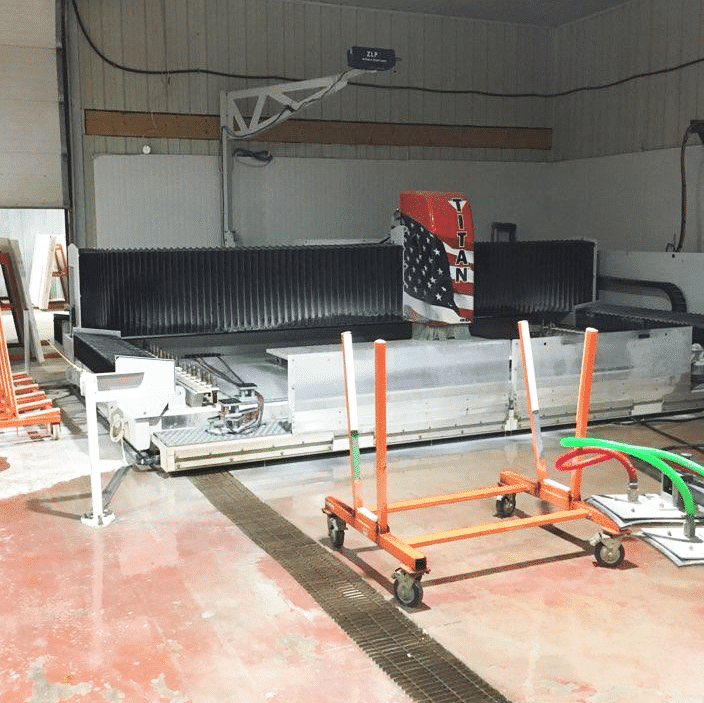

Revolutionizing Workflows with the TITAN® CNC Router

The TITAN CNC Router has significantly streamlined Jim’s polishing production, reducing labor needs. This increase in efficiency has been crucial for their workflow. Jim emphasizes the TITAN’s precision when it comes to polishing. “The accuracy of the TITAN is absolutely amazing.” Additionally, Jim appreciates the machine’s user-friendly nature. He happily shares, “It’s straightforward to operate, allowing us to maximize our time.”

A Proud Park Industries Advocate

Jim’s partnership with Park Industries has been transformative, boosting efficiency, enhancing product quality, and aligning with his retirement plans. He praises Park’s support, saying, “Park’s been a huge part of my success, keeping my machines running smooth and efficient.” This support and reliability have allowed Jim to manage everything himself, improving his work-life balance.

Proudly an all-Park shop, Jim even ensured the color of his new Ford truck matched his machines, demonstrating his deep trust in Park. Jim’s experience displays the impact of investing in reliable machinery, noting, “If you want to be a grow in this business, there is only one choice for who you should partner with: Park Industries.”

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.