Founded in 2017, Evolution Marble & Granite quickly became a leading countertop fabricator in New Jersey, thanks to a strong partnership with Park Industries® which started in 2018. Co-owner Joe DeMelo has since relied on industry-leading machines like the FUSION® CNC Sawjet, FASTBACK® II Edge Polisher, and SABERjet™ XP Sawjet to help drive the company’s growth.

The Evolution of Evolution Marble & Granite

Over the past four years, Evolution Marble & Granite has grown from a four-man crew producing 1,200 square feet per week to an 18-man team producing close to 5,000 square feet per week. “Our growth with Park Industries® has been unmatched,” says Joe. This partnership with Park Industries® has laid the foundation for their success, allowing them to consistently deliver both high-quantity and high-quality work.

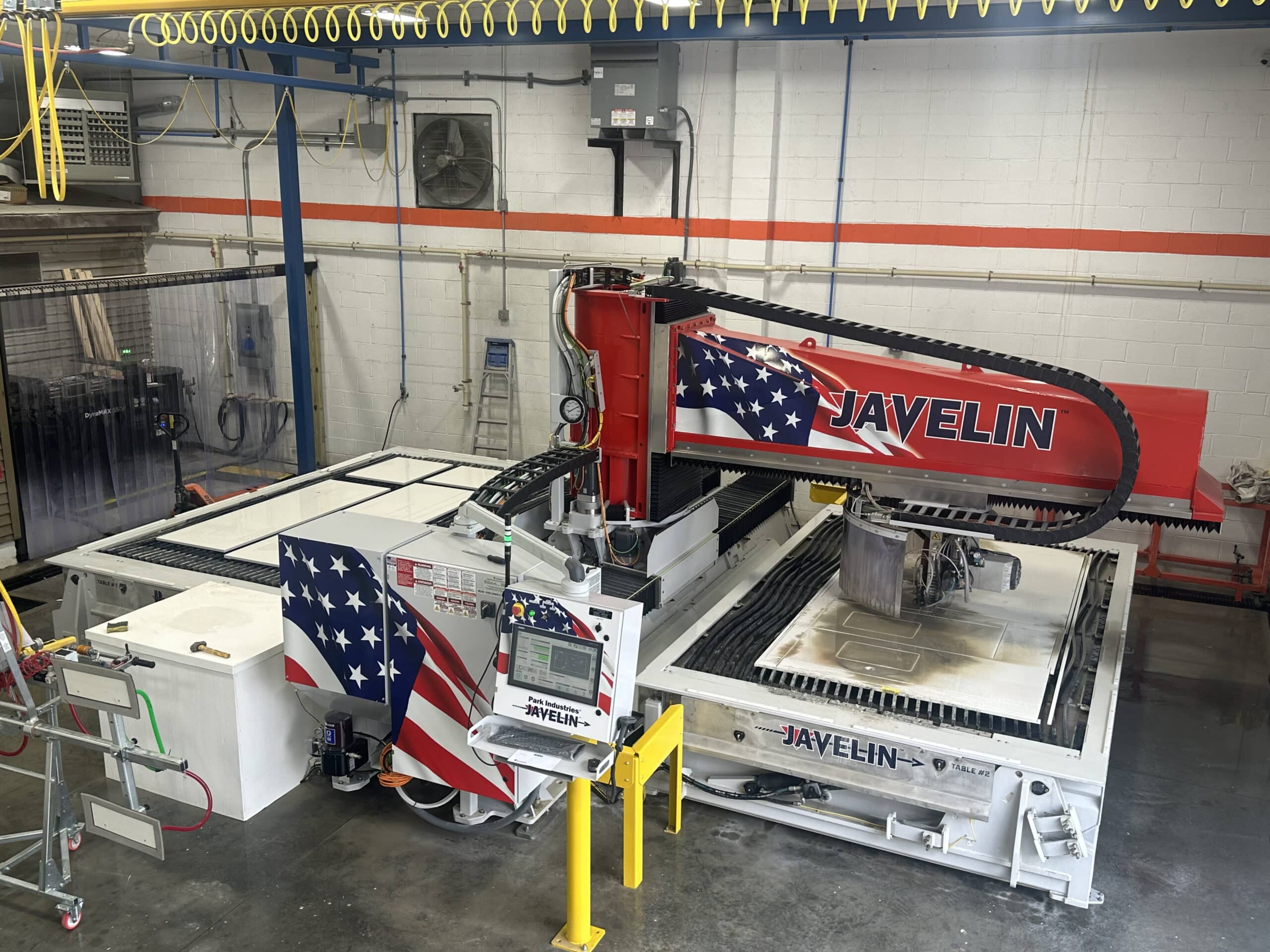

Evolution has grown to have a fleet of Park machinery, including the last three generations of Park sawjets: FUSION, SABERjet XP, and JAVELIN™. This powerful trio allows them to handle the high production demands of their primarily commercial work, efficiently executing complex miters across all their sawjets.

Despite being a company just seven years old, their strategic investment in this advanced equipment underscores the significant ROI they’re achieving, reflecting both their operational excellence and impressive business growth.

Production that Never Stops with the JAVELIN CNC Sawjet

In July 2024, Evolution added the JAVELIN CNC Sawjet to their operations. This addition was a game-changer, enabling the company to handle larger projects and significantly boost daily production. “The JAVELIN has been awesome. We’ve always loved the idea of having a two-table, and when we saw the JAVELIN’s design, we had to get it,” Joe shares.

The JAVELIN comes with two tables with slab loader tanks, which allow for fast and easy loading with a clamp. Despite its two-table design, the JAVELIN™ has a very small footprint, making it an ideal fit for their shop where space is at a premium, especially on the East Coast.

With its two-table design, the JAVELIN has pushed production to nearly 1,000 square feet per day, primarily focusing on commercial projects. Joe notes, “Having two tables makes it feel like it never stops!”

The JAVELIN has also reduced the need for late nights at the shop. Joe reflects, “Before, I would have had a lot of late nights along with a couple of helpers, but now we haven’t had that problem since we got the JAVELIN.”

Solving Bottlenecks with the TITAN® CNC Router

Evolution also recently upgraded their edge finishing capabilities by adding the TITAN 4800 CNC Router in December 2023. The TITAN quickly became essential to their workflow. “With the TITAN to complement our cutting production, we’re getting more jobs out the door than ever before with less stress,” Joe states.

The decision to invest in the TITAN was driven by challenges with bottlenecks. “We had a real bottleneck on our commercial projects, so we got a TITAN to help solve that,” Joe explains. The TITAN has since streamlined their workflow, significantly boosting productivity.

Keeping the Shop Running with Next-Day Parts

Offering next-day parts delivery, Park Industries® provides quick support to Evolution when their machines require maintenance. Joe highlights the efficiency of Park’s Next-Day Parts system: “We order parts at 4 PM, and we have them by 8:30 AM the next day!” This quick response keeps their shop operations running smoothly and without interruptions.

Nothing Else Like Park Industries®

Beyond the machinery and parts support, it’s the partnership with Park Industries® that has truly empowered Evolution Marble & Granite to grow. “The team at Park definitely goes the extra mile. They’ve gone over and beyond to make me happy,” Joe asserts. “There’s nothing else in the market like Park Industries®.”

Evolution Marble & Granite’s story showcases the impact of investing in the right equipment and the right company behind that equipment. With Park Industries® by their side, they continue to establish and propel their company forward. “Like I said before, we wouldn’t be where we are without Park Industries® machinery.”

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.