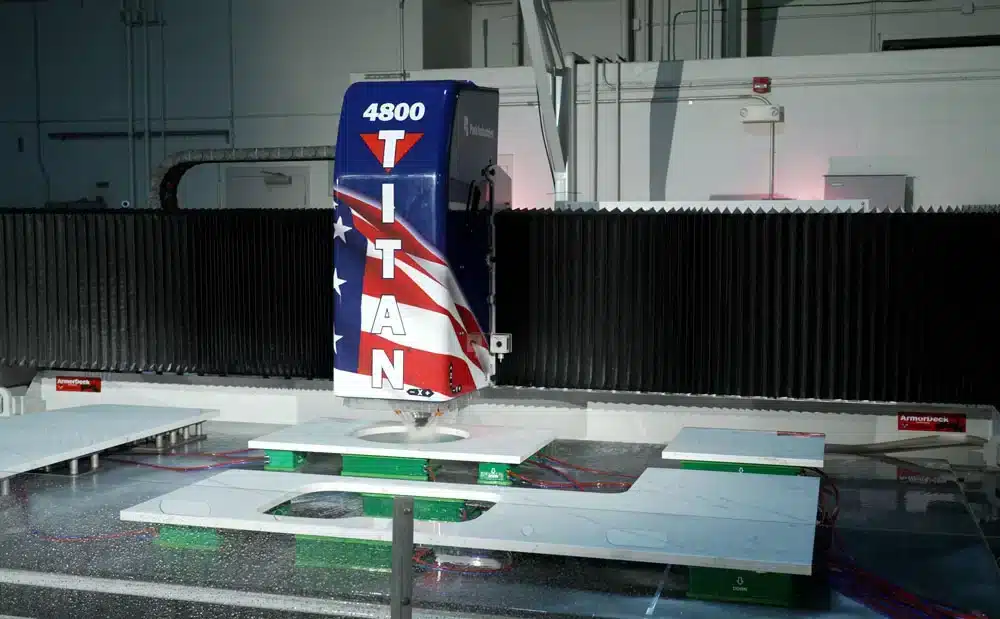

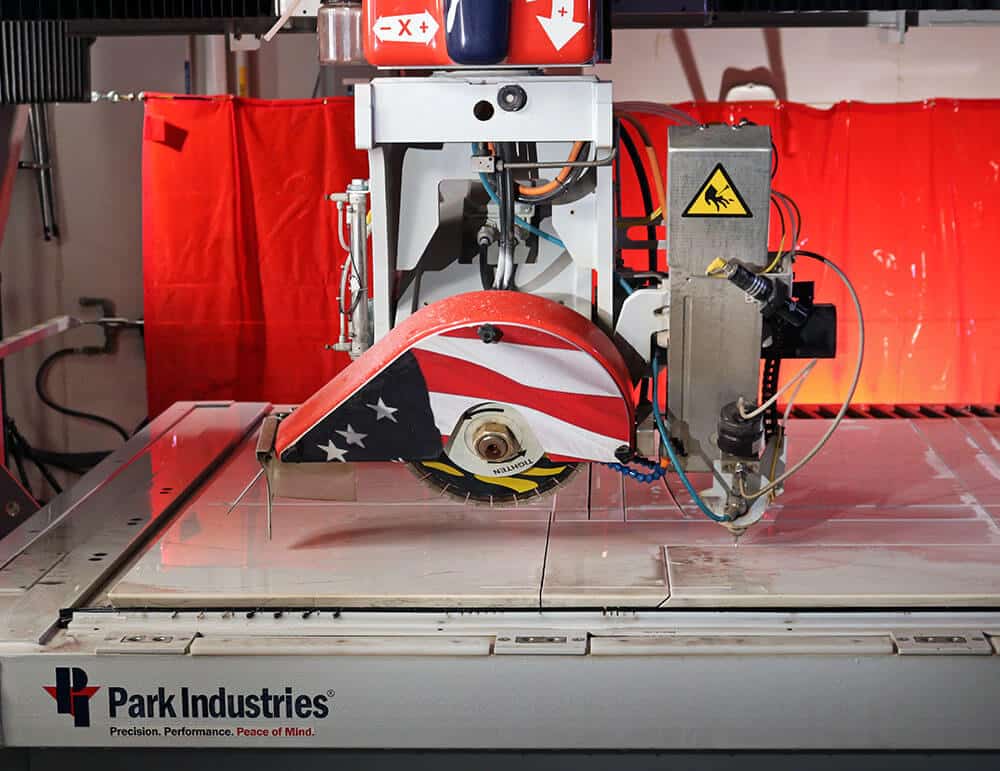

TITAN® Fab Center

CNC Saw + Router

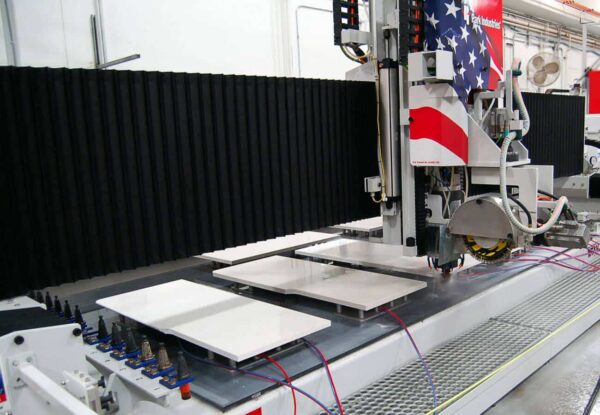

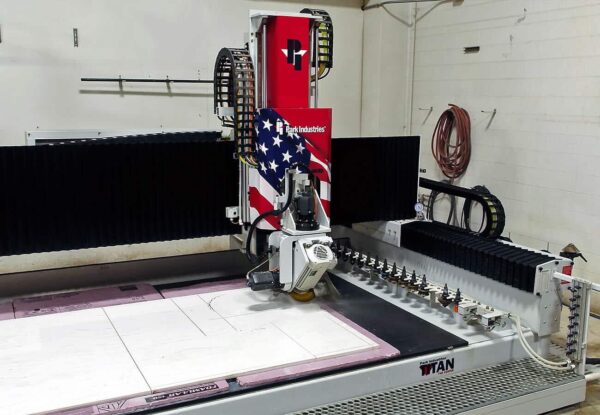

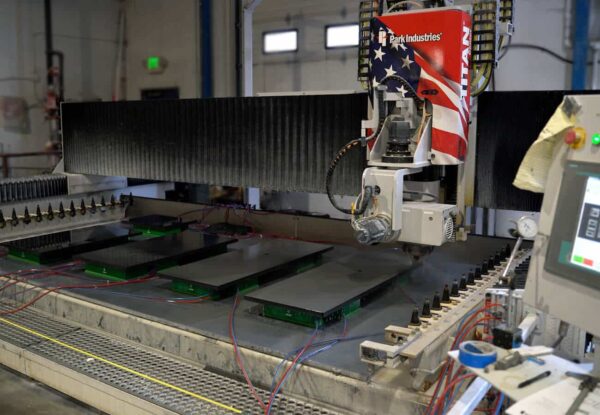

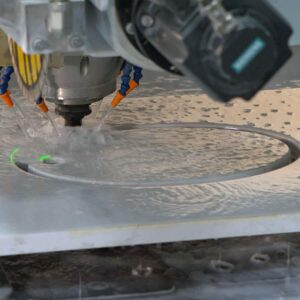

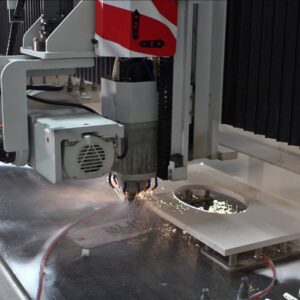

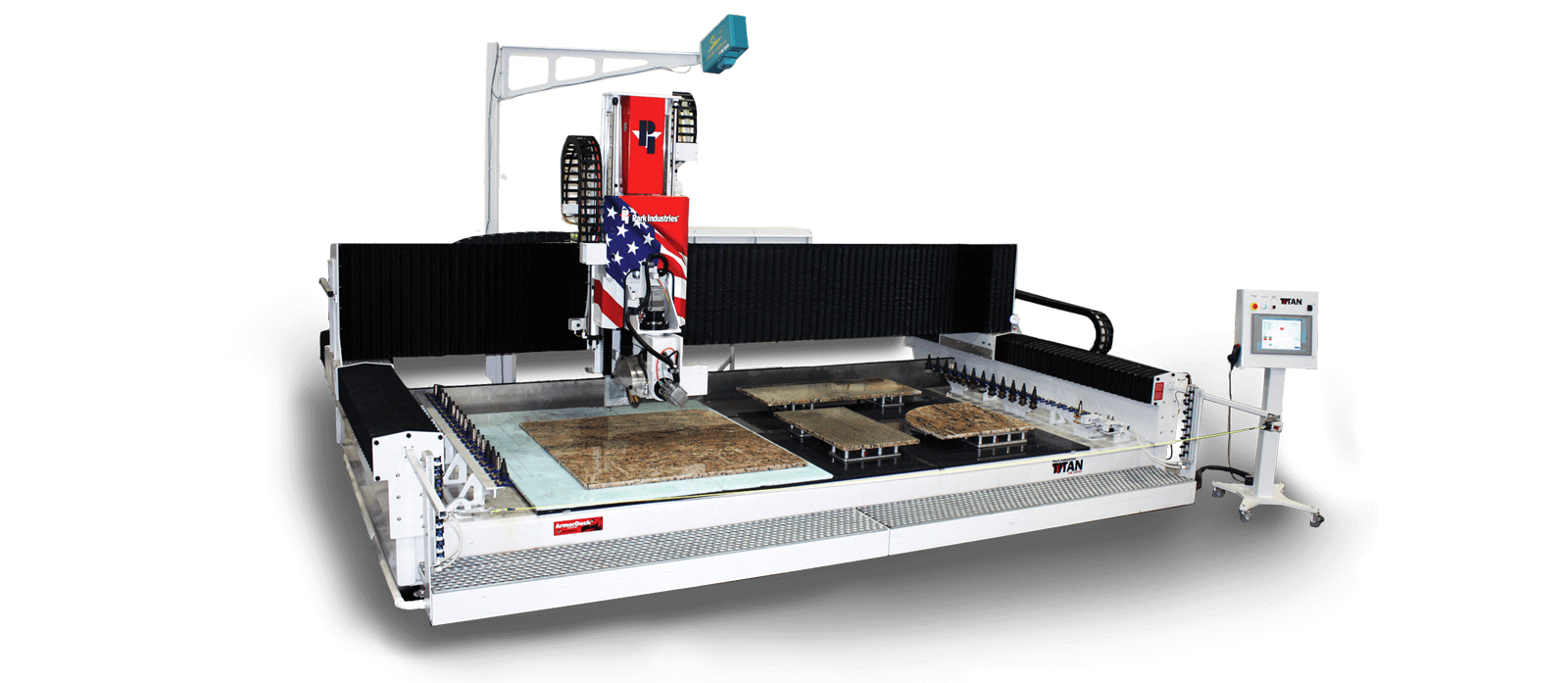

The TITAN® Fab Center combines efficient sawing and accurate edging capabilities in one machine. With just 2 employees working an 8-hour shift, you can produce 120 square feet of finished countertops with the TITAN Fab Center. Cut, miter, shape, and polish all on one machine. By integrating a Fab Center into your operations, you may be able to reduce your labor costs by up to 50% and your square foot productions costs by nearly 40%.

CUT & EDGE

COUNTERTOPS0-47°

Mitering24 HP

SPINDLE

Choose your Region

Please choose your region and fabrication type below.

Watch Videos

Key Features

- The ultimate combination of efficiency and productivity.

- Layout and stone image capture capability

- 24 HP 10,000 RPM Quantum Electro Spindle backed by Park’s 5-year warranty

- Laser positioning to easily place the vacuum cups and parts in place

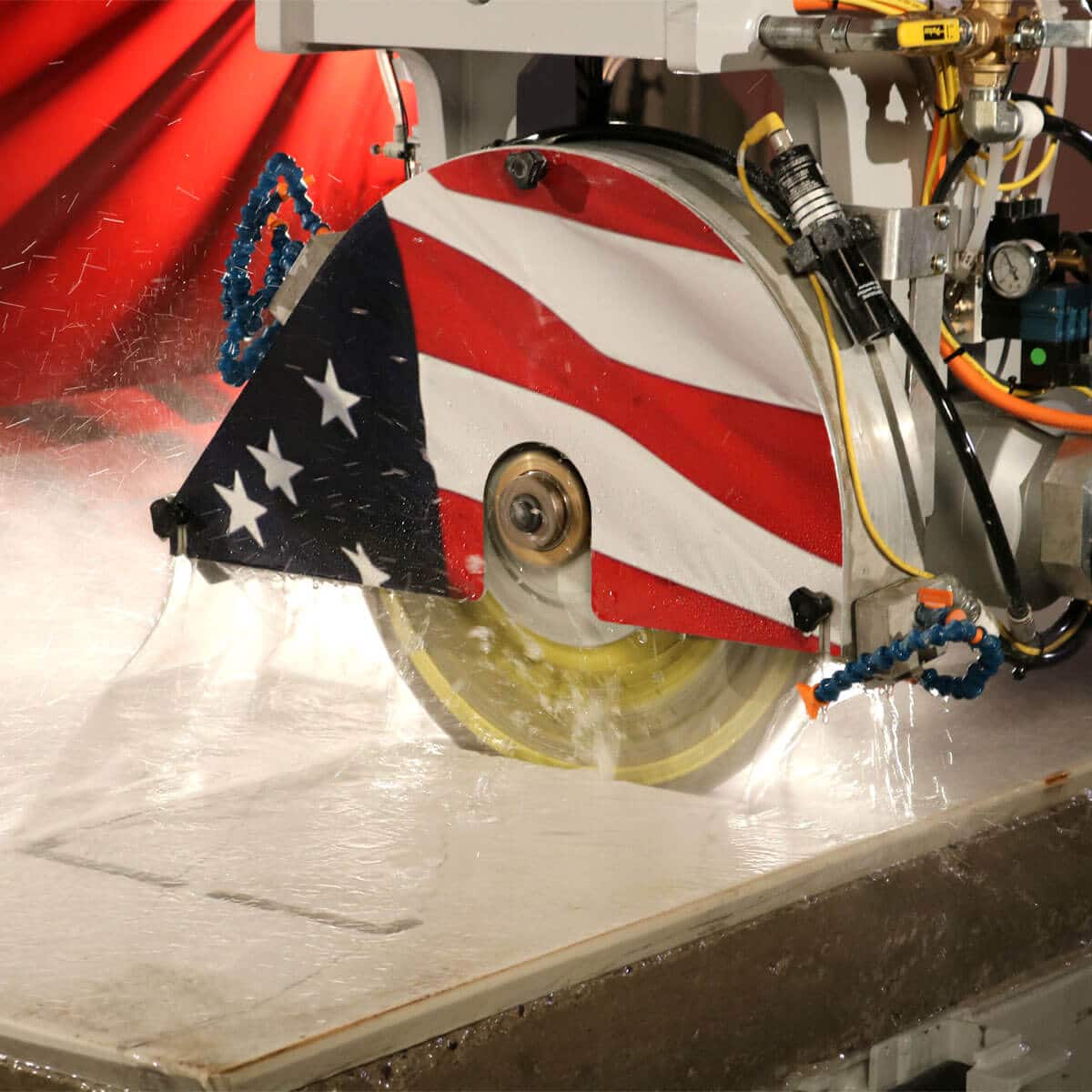

- 15 HP Saw Arbor Motor

- 0–47° CNC Servo Driven Miter Capability

- Rugged, durable, and ready to tackle the hardest jobs.

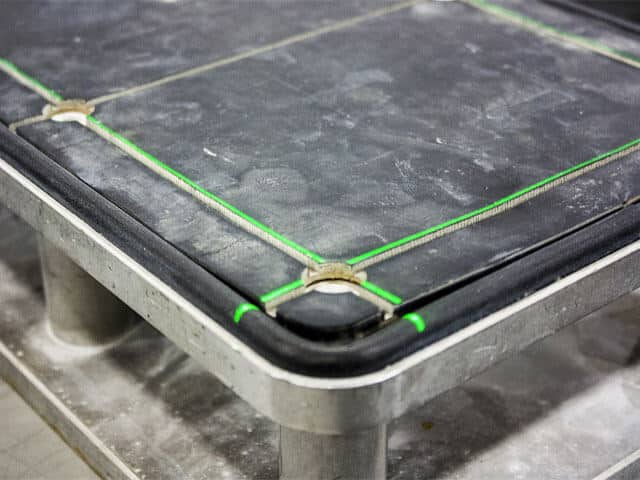

Our unique ArmorDeck work surface holds pieces in place with a powerful suction for greater production speed without parts shifting. In fact, it has 30% better holding power than aluminum surfaces and will never corrode or dent, saving you even more money and ensuring a quality product.

- Operation so simple, you can forget all about codes.

Park’s user-friendly iTEC Interface technology is an operator’s best friend. This intuitive barcoded system is programmed specifically for your operation. Once scanned, the machine automatically loads and starts.

- Integrated Tool Management™

Our Integrated Tool Management™ (ITM) system extends tool life by up to 50% by automatically monitoring, measuring, and compensating for tool wear. This precise and dependable system significantly reduces the need to reshape your tools, saving you thousands of dollars in tooling costs.

- Exclusive Armor Shield Protection

The Armor Shield Protection is a process that protects critical machine parts enhancing corrosion and wear resistance. It extends the lifespan of critical components by protecting the parts from the harsh, wet environment, increasing machine uptime.

The Armor Shield is not a plating or surface coating process. This unique process produces an aesthetic black finish that impregnates the material for strength and durability. The treatment actually changes the composition of the material on the outside of the part.

- Alphacam programming with exclusive Park EZ™ Buttons

Programming made FAST and SIMPLE! Park EZ™ Buttons, exclusive on Park Industries CNC machinery, make common programming tasks EZ.

Paired with Alphacam’s world-class CAD software, use over 40 built-in Park EZ™ buttons to eliminate tedious programming steps and increase your productivity. Save 60% or more of your programming time and clicks!

- The Machine to Grow With

The power of this machine will allow you to transform your shop into a digital shop. As your business grows, you can add a CNC Saw or CNC SawJet to your operations and utilize the Fab Center for primarily routing and a backup sawing station if needed. The versatile Fab Center allows you to digitally fabricate and is a great path for expanding your production capacity in the future.

Specifications

| Select up to 3 models to compare key specs | TITAN® Fab CenterView Layout Drawing | |

|---|---|---|

| Spindle Motor | 24 hp | |

| Spindle Type | Quantum Electro Spindle | |

| RPM's | Up to 10,000 | |

| Work Area Size | 8' x 14' 4-1/2" | |

| Tool Pockets | 34 | |

| Vacuum Cup Options | Blick, BVC | |

| Slab Thickness | 1-6 cm | |

| Sawing Capabilities | Yes | |

| Blade Size | 14" - 16" | |

| Arbor Motor | 15 hp | |

| Mitering | 0-47° | |

| Monoblock Design | Yes | |

| Overhead Laser Height | 12' 8.625" | |

| Footprint including clearance (L x W x H) | 27'5.25" x 22'4.375 x 7'5.25" | |

| Weight | 26,000 lbs. |

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.

The Titan Fabcenter is a workhorse…We bought it primarily for custom work, especially miters. It helped us grow to where we could add a voyager cnc saw and Fastback 2 a few years later. Now it can focus just on doing edges while still giving me a backup saw.

Yes, I recommend this product.