Porcelain is a trending material choice for clients who love sleek, modern surfaces. This engineered material is incredibly durable making it more resistant to heat and scratches. Whether you’re cutting porcelain slabs for countertops, backsplashes, or wall features, using the correct tools and techniques is essential to achieve the precision and smooth finish your clients expect.

This article outlines the key requirements for cutting porcelain and how Park Industries® can optimize your fabrication process.

Check out the full video here!

Essential Requirements for Cutting Porcelain

Cutting porcelain requires a specialized diamond blade, as porcelain is an incredibly hard and brittle material. Diamond blades embedded with synthetic diamonds are essential for handling porcelain’s unique density and hardness, providing clean cuts that minimize chipping and preserve the slab’s integrity.

However, the diamond blade alone isn’t enough. A water-cooled system is crucial when working with porcelain to manage the heat and control dust produced during cutting. This cooling process reduces the risk of cracking and ensures a clean, polished edge, which is especially important given porcelain’s tendency to chip.

For fabricators looking to optimize their porcelain-cutting capabilities, CNC saws and sawjets provide the precision and efficiency needed for intricate cuts and consistent results, maximizing efficiency, and reducing material waste.

How to Cut Porcelain with a handheld saw

If you’re cutting porcelain manually without CNC saws, the process requires a steady hand and careful attention to detail. Start by marking your cut line on the porcelain slab using a grease pencil or chalk. This guide will help ensure accuracy throughout the cutting process.

Next, securely clamp the slab to prevent any movement while cutting. Use a handheld saw equipped with a diamond blade rated for porcelain, and make slow, steady passes. Begin by lightly scoring the marked line to create a shallow guide, which helps prevent the blade from wandering during deeper cuts.

Because porcelain generates significant heat, always use water to cool the blade and control dust. Make shallow initial passes, gradually increasing the depth with each pass until you cut through the slab completely. With patience, the right tools, and proper technique, you can achieve smooth, precise cuts that highlight porcelain’s elegant finish.

porcelain Cutting Solutions with park

When precision, speed, and efficiency are critical, Park Industries® offers industry-leading equipment designed specifically for fabricators working with porcelain. Here’s how our machines can elevate your shop’s capabilities:

JAVELIN™ CNC SawJet

The JAVELIN™ CNC Sawjet delivers the perfect balance of power and precision. Utilizing a diamond blade and integrated waterjet, the JAVELIN is built for high-accuracy cutting, whether you’re executing straight cuts or intricate designs in porcelain. The JAVELIN’s waterjet minimizes material waste and reduces the need for secondary finishing, maximizing efficiency.

What truly sets the JAVELIN apart is its impressive speed and accuracy, making it ideal for both high-production and custom work. Its compact footprint and configurable design allow it to integrate seamlessly into any shop layout. Additionally, the JAVELIN’s accessible table design, with access on all three sides, further boosts efficiency by simplifying material handling. With optimized waterjet technology, fabricators can tackle porcelain projects with precision, speed, and maximized slab yield.

SABERjet™ XP CNC SawJet

Power up your production with the SABERjet™ XP CNC Sawjet, which boasts an industry-leading 27 hp arbor motor and versatile 5-axis waterjet capabilities. Combining the efficiency of a diamond blade with advanced cutting technology, the SABERjet XP excels at delivering precise straight cuts and detailed mitering with ease.

Whether you’re handling simple or complex designs, this machine adapts to your shop’s needs, improving both productivity and precision.

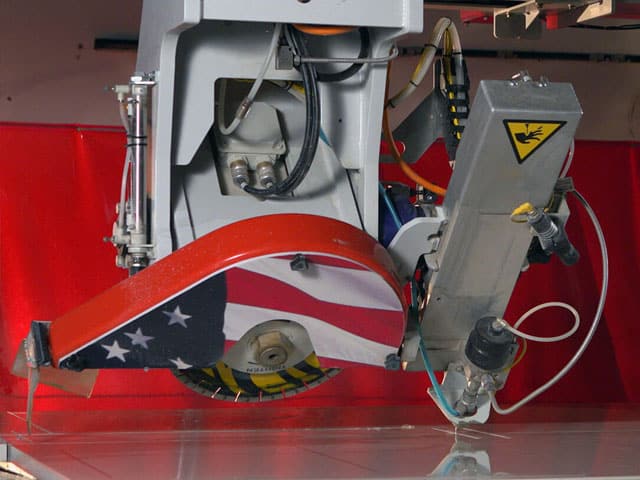

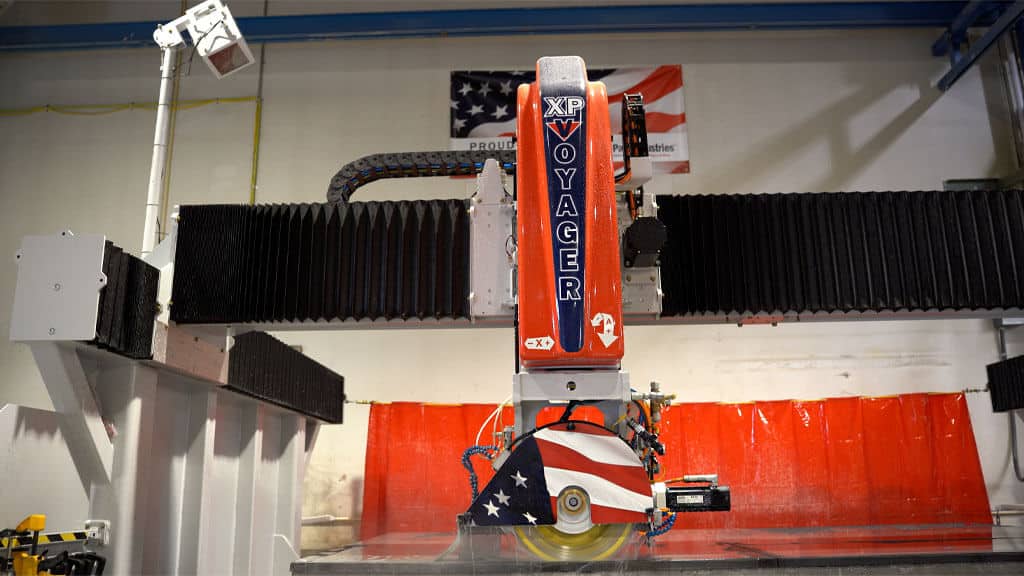

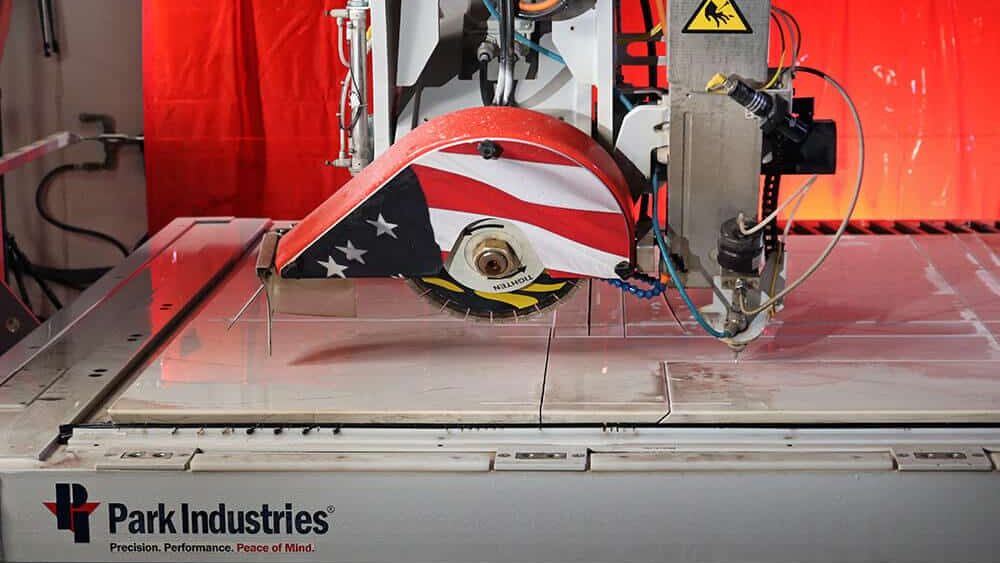

VOYAGER™ XP CNC Saw

Voyage into digital fabrication with the VOYAGER™ XP CNC Saw. The VOYAGER XP CNC Saw offers full automation for large-for a variety of cuts, including straight, miter, tightcut, and even profiles. With the flexibility to run in both manual and automatic modes, it adapts to any cutting task with ease. The VOYAGER XP also features an auxiliary spindle, expanding its capabilities to include tasks like drilling faucet holes, cutting sinks, using a leatherhead, or even engraving, making it an incredibly flexible tool for diverse fabrication needs.

Its advanced controls ensure high-precision cuts, reducing the need for post-processing, which results in increased production efficiency and minimized material waste.

YUKON® II bridge Saw

Rely on the YUKON® II Bridge Saw to boost your output with speed, reliability, and accuracy. Built for straightforward operation and unmatched dependability, this bridge saw is ideal for meeting high production demands without compromising precision.

With the YUKON II, fabricators can achieve precise cuts on large slabs, optimizing both speed and consistency. Its robust design and user-friendly controls make it a solution for fabricators seeking efficiency and durability in their stone-cutting process.

Why Choose Park?

Park Industries® has served the stone industry since 1953. With our focus on precision, performance, and peace of mind, you can know that each piece of equipment we sell will meet your needs. We believe that the best equipment should come with unparalleled support, so you can focus on what you do best — fabricating high-quality stone products.

Contact us today and equip your shop with proven and profitable solutions, backed by the industry’s best customer support.

Ready to learn more?

Explore additional resources on cutting other materials with the right tools and techniques:

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.