To fabricate stone with precision and efficiency, it all starts at the backbone of your shop – your cutting machine. From trusty manual bridge saws to high-tech CNC sawjets, the right saw sets the stage for the rest of the process. At Park Industries®, we’ve spent over 70 years making machines that help you cut cleaner, work faster, and get more done.

Dive into this guide of our countertop cutting machines and discover the perfect solution for your needs.

CNC Sawjets

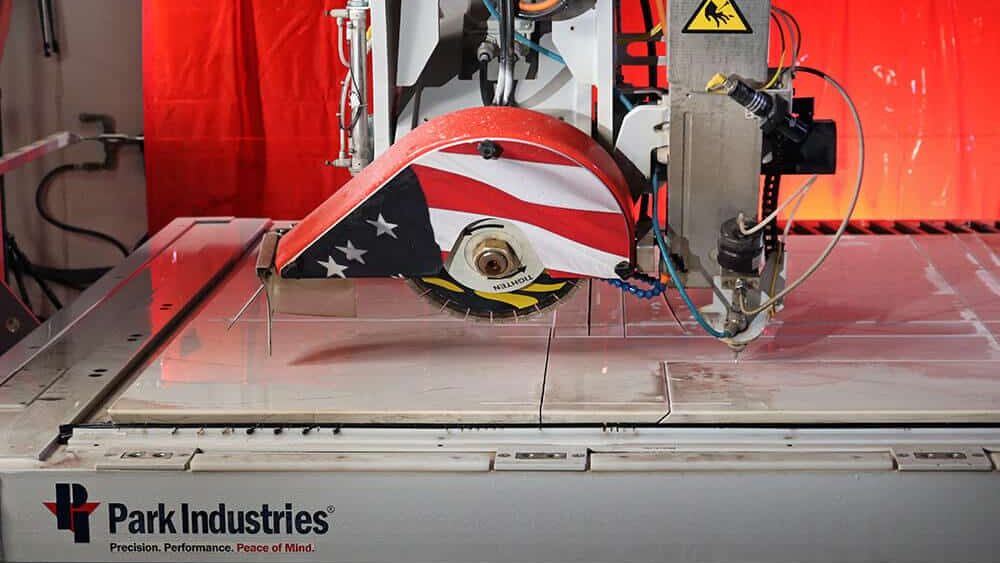

CNC Sawjets combine the cutting power of a saw blade with the fine precision of a waterjet, giving you the best of both worlds. They’re perfect for intricate designs, custom mitering, and high-speed production. Park Industries offer two styles of CNC Sawjets, both come with multiple tank options and are available in a single table or two table model.

These machines are engineered for CNC/auto operation, with the option for manual control when customization is required.

JAVELIN™ CNC SawJet

The JAVELIN CNC Sawjet delivers the perfect balance of power and precision. Utilizing a diamond blade and integrated waterjet, the JAVELIN is built for high-accuracy countertop cutting, whether you’re executing straight cuts or intricate designs. The JAVELIN’s waterjet minimizes material waste and reduces the need for secondary finishing, maximizing efficiency.

What truly sets the JAVELIN apart is its impressive speed and accuracy, making it ideal for both high-production and custom work. Its compact footprint and configurable design allow it to integrate seamlessly into any shop layout. Additionally, the JAVELIN’s accessible table design, with access on all three sides, further boosts efficiency by simplifying material handling. With optimized waterjet technology, fabricators can tackle projects with precision, speed, and maximized slab yield.

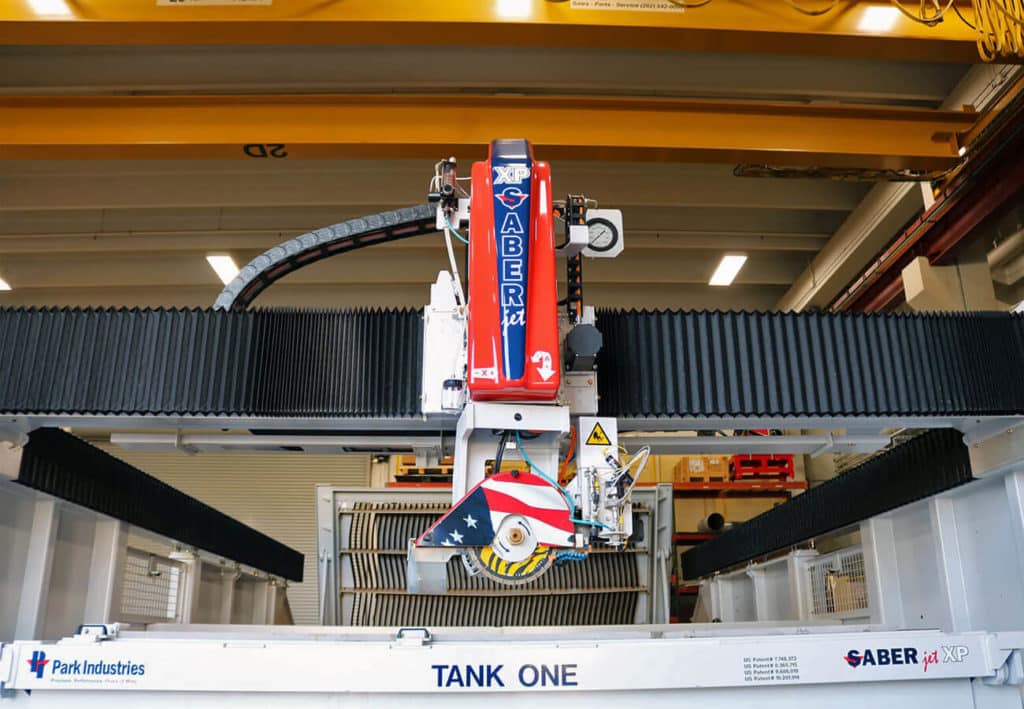

SABERjet™ XP CNC SawJet

The SABERjet XP CNC Sawjet offers the same cutting-edge capabilities as the JAVELIN® with one key distinction: its monoblock design. This feature provides unmatched flexibility, making it easier to relocate or adjust to future facility changes.

Engineered for precision and efficiency, the SABERjet XP combines a powerful saw blade with waterjet technology to tackle straight cuts, mitering, and intricate designs with ease. Whether scaling production or managing custom projects, this versatile sawjet delivers consistent, top-tier results.

CNC Saws

CNC Saws are built for precision countertop cutting but offer the versatility to do much more. With options to leather, mill, flute, engrave, and route, these machines handle a wide range of tasks with ease. Their productivity and adaptability make them a top choice for fabricators needing accurate cuts and additional capabilities.

These machines are designed to operate in CNC/auto mode for maximum efficiency, with the flexibility to switch to manual mode for specialized tasks.

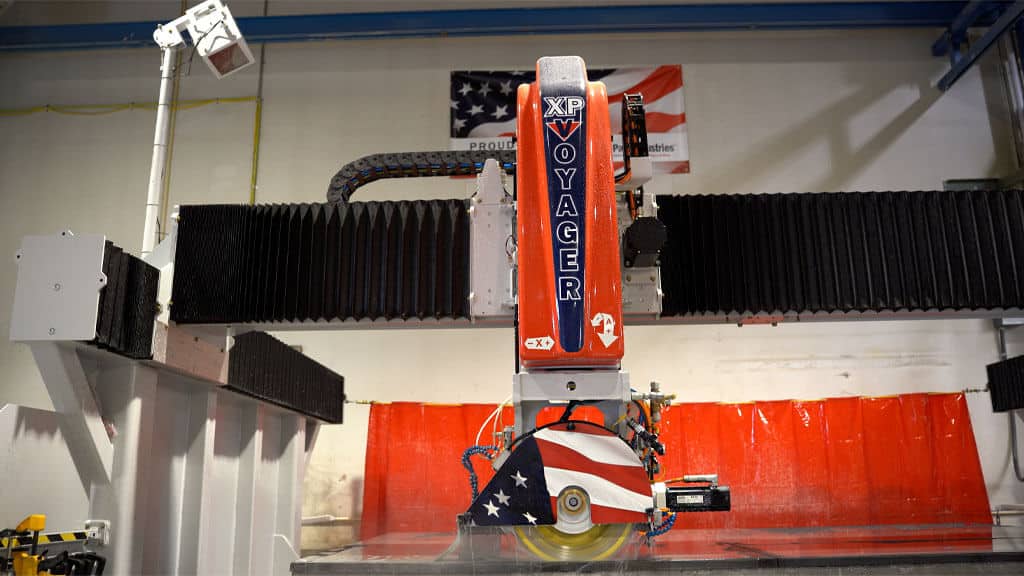

VOYAGER™ XP CNC Saw

What sets the VOYAGER XP CNC Saw apart is its auxiliary spindle, which expands its capabilities to include drilling faucet holes, cutting sinks, and more. By reducing material waste and minimizing the need for post-processing, this machine saves time while maintaining the precision your customers expect.

Whereas sawjets use a waterjet for sinks, faucets, and more – the VOYAGER XP CNC Saw offers an auxiliary spindle to core faucet holes, mill out sinks, and more. This auxiliary spindle offers greater versatility then a waterjet, but its processing speed is slightly slower.

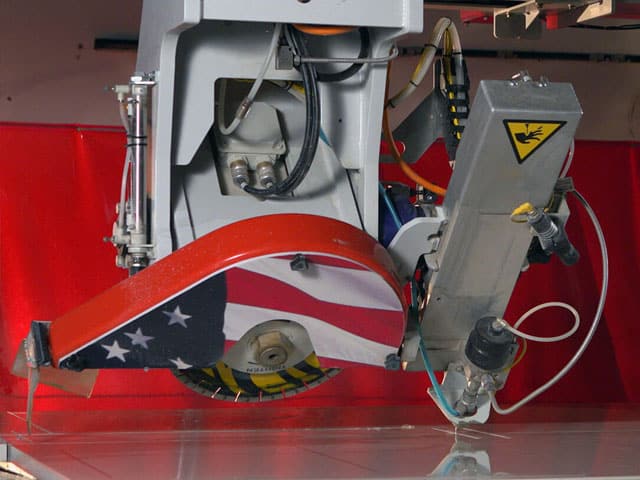

Bridge saws

For heavy-duty applications, our Bridge Saws deliver consistent, reliable performance. Designed to handle large slabs with precision, these machines are built for durability and high production.

Bridge saws are operated manually, providing fabricators with complete control over every cut. The YUKON II Bridge Saw also features a semi-auto mode for added versatility and efficiency.

YUKON® II bridge Saw

Experience durability and precision with the YUKON II Bridge Saw, designed for fabricators seeking reliable performance and ease of use. Featuring a 360-degree rotating tilt table for seamless cut alignment and intuitive controls, the YUKON II simplifies the cutting process while delivering exceptional accuracy.

Capable of mitering with precision, this bridge saw is a durable solution for those transitioning from hand or rail saws, offering improved speed and accuracy. With the YUKON II, fabricators can confidently handle diverse cutting needs with ease and consistency.

miter saws

When it comes to flawless mitered edges, our Miter Saws deliver. They have one job and one job only: deliver precise miters with every cut. These work more like a line machine then a saw table.

Miter saws operate in manual mode, ensuring precise results with an operator present for each cut.

Crosscut™ xp Miter Saw

The CrossCut XP Miter Saw is designed with one goal in mind: delivering perfect miters every time. Its expert engineering ensures smooth, accurate cuts, making it an key tool for fabricators focused on achieving high-quality results. From countertops to pavers, the CrossCut XP excels at creating the flawless edges your customers demand.

With its emphasis on repeatability and ease of operation, the CrossCut XP streamlines the mitering process, saving time while maintaining exceptional precision.

Why Choose Park?

At Park Industries®, we go beyond providing machines — we deliver peace of mind. Our innovative, easy-to-use equipment is designed to improve your workflow, reduce costs, and maximize your profits. Backed by unparalleled support and over 70 years of expertise, we’re here to help you succeed.

Contact us today and equip your shop with proven and profitable solutions, backed by the industry’s best customer support.

Adding the right machinery provides real results. Understand the impact at these shops.

Adding the right machinery provides real results. Understand the impact at these shops.